Last updated on: August 29, 2025

As a civil engineer, I’ve learned how important it is to understand the Civil Engineering Basic Knowledge for construction works. There are over 100 key points to remember, ranging from building sizes to green building methods. A single mistake can cause significant delays and safety risks.

This guide is designed to help you grasp the essential civil engineering basics. It’s useful for both experienced engineers and newcomers. You’ll find key concepts and practical tips to manage your projects effectively.

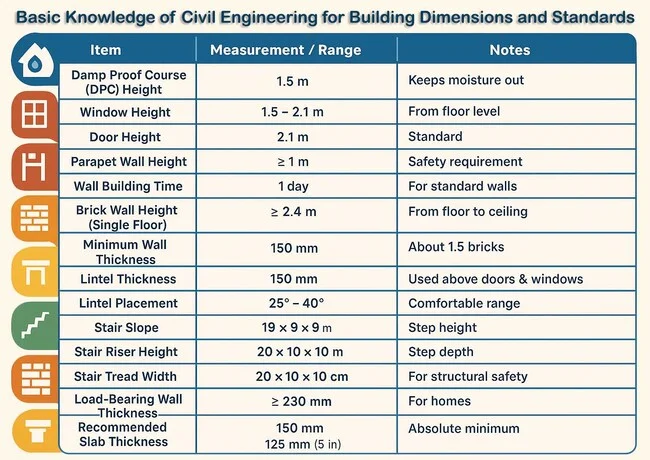

Basic Knowledge of Civil Engineering for Building Dimensions and Standards

To begin, knowing the standard sizes for building parts is super important for any construction site. This is one of the foundations of Civil Engineering Basic Knowledge for Site Works, helping ensure safety and compliance.

- Damp Proof Course (DPC) Height: 1.5 meters (keeps moisture out, very important!)

- Window Height: 1.5 to 2.1 meters

- Door Height: 2.1 meters

- Parapet Wall Height: At least 1 meter

- Wall Building Time: One day for standard walls

- Height of Brick Wall for Single Floor: At least 2.4 meters

- Minimum Wall Thickness: 150 mm (about 1.5 bricks)

- Lintel Thickness: 150 mm (used above doors and windows)

- Lintel Placement: Above doors and windows

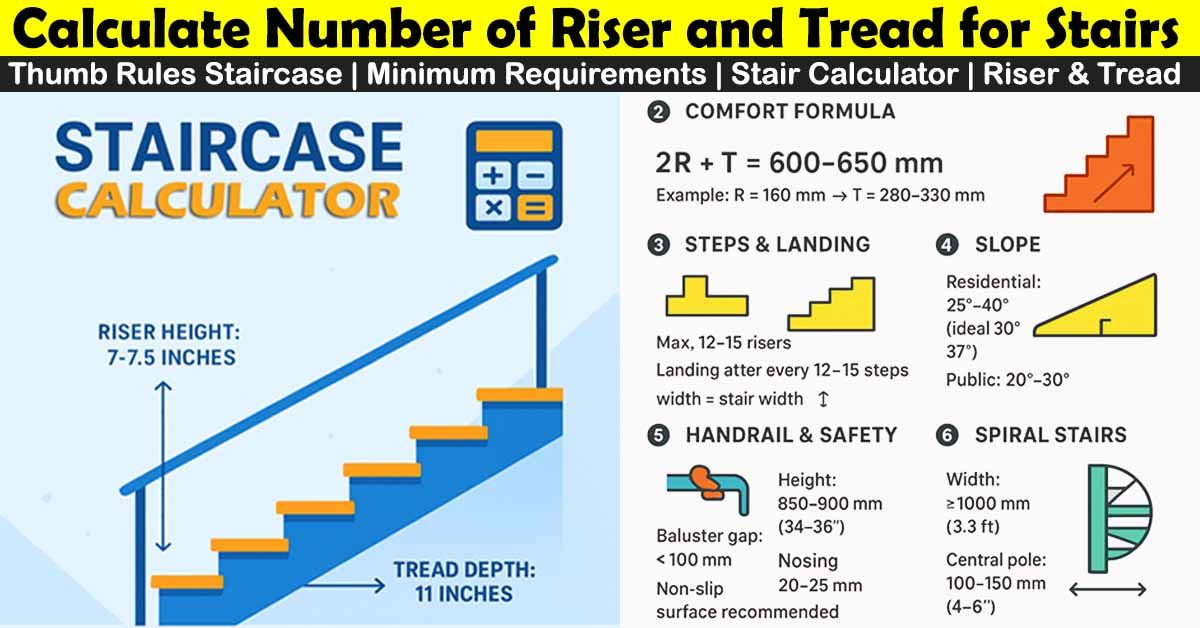

- Stair Slope: Between 25° and 40°

- Stair Riser Height: At least 150 mm

- Stair Tread Width: At least 230 mm

- Standard Size of Brick – without mortar: 19 x 9 x 9 cm

- Standard Size of Brick – with mortar: 20 x 10 x 10 cm

- Plinth Height Above Ground: At least 450 mm

- Door Opening Size: 900 mm x 2100 mm

- Window Opening Size: 1200 mm x 1500 mm

- Load-Bearing Wall Thickness: At least 230 mm

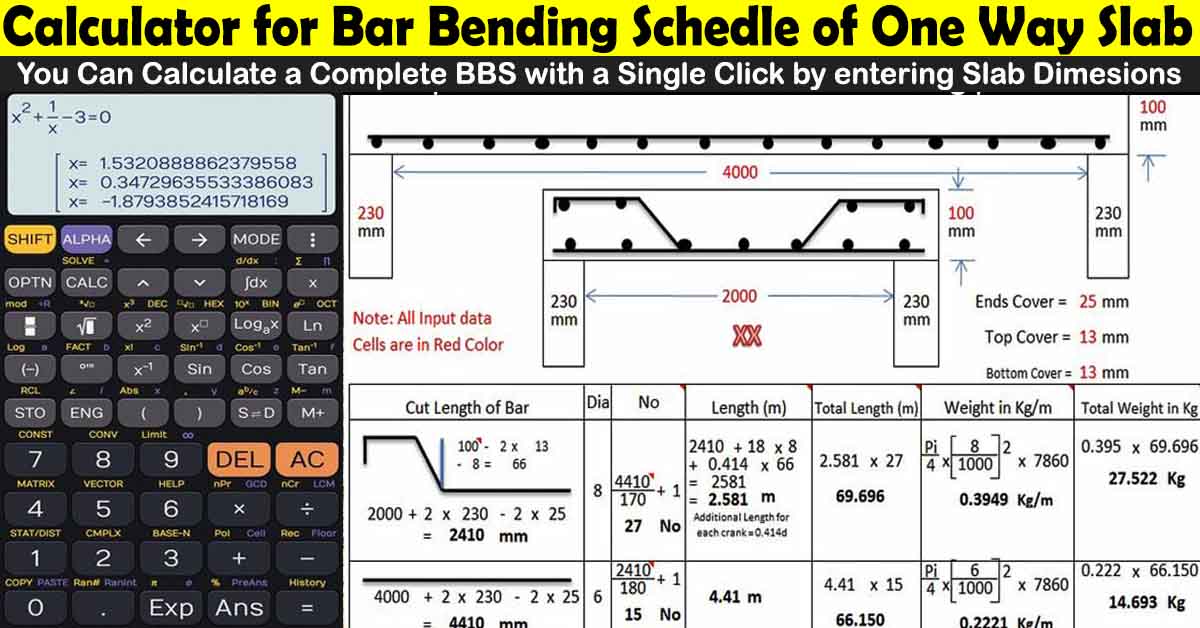

- Recommended Slab Thickness: 150 mm for homes

- Minimum Slab Thickness: 125 mm (or 5 inches)

These measurements help make buildings strong and comfortable. For example, keeping the DPC at 1.5 meters stops dampness, a common problem on construction work sites.

Civil Engineering Basics Fundamentals for Concrete and Reinforcement

Concrete is the backbone of Civil Engineering Basic Knowledge. From mix ratios to reinforcement details, these points cover what you need for RCC (Reinforced Cement Concrete) elements:

- Minimum Diameter of Bars in Slabs: 8 mm

- Minimum Diameter of Bars in Columns: 12 mm

- Approximate Diameter of Bar for Slabs: 12 mm or 1/8th of slab thickness

- Maximum Diameter for Dowel Bars: 12 mm

- Grade of Concrete for R.C.C Slabs: M20 (1:2:4 mix ratio)

- Mix Ratio for M5: 1:5:10 (Cement : Sand : Agg)

- Mix Ratio for M7.5: 1:4:8

- Mix Ratio for M10: 1:3:6

- Mix Ratio for M15: 1:2:4

- Mix Ratio for M20: 1:1.5:3

- Mix Ratio for M25: 1:1:2

- Compressive Strength of Concrete Test: Conducted at 7 days, 14 days, and 28 days

- Full Strength of Cement Achieved at: 28 days

- No Lapping Provided for Bars Over 36 mm Diameter

- Min Number of Bars in Square RCC Columns: 4 bars

- Min Number of Bars in Circular RCC Columns: 6 bars

- Lapping of Bars Should Not Be Provided in High-Stress Areas

- Min Clear Cover for Reinforced Concrete Elements (Slabs): 20 mm

- Minimum Clear Cover for Beams: 25 mm

- Minimum Clear Cover for Columns: 40 mm

- Minimum Clear Cover for Footings: 50 mm

- Minimum Overlap Length for Tension Steel: 40 times the diameter of the bar

- Minimum Overlap Length for Compression Steel: 24 times the diameter of the bar

- Unit Weight of R.C.C (Reinforced Cement Concrete): 24 kN/m³

- Initial Setting Time of Cement: 30 minutes

- Final Setting Time of Cement: 600 minutes or 10 Hours

- Dimensional Tolerance for Concrete Cubes: ±2 mm

- Free-Fall Height for Concrete Placement: 1.5 meters Max

- Formwork Removal Time for Slabs: 14 days for props

- Formwork Removal Time for Beams: 21 days for props

- Construction Joint Placement: Ideally at one-third span in beams and slabs

- Curing Time for Concrete Elements: Minimum 7 days, ideally 28 days

- Maximum Allowable Crack Width in Concrete: 0.3 mm

- Minimum Spacing Between Columns: Based on design, but typically 3.0 to 7.5 meters

Pro tip: Always test compressive strength at 7 days, 14 days, and 28 days to confirm your concrete’s performance on site.

Mortar, Masonry, and Construction Materials Specifications

Civil engineering site knowledge about Mortar and brickwork play a crucial role in constructing durable walls and providing a solid base for plastering. Here are the simple details you need:

- Mortar Mix for Load-Bearing Walls: 1 part cement to 3 or 4 parts sand (strong mix for important walls).

- Mortar Mix for Non-Load-Bearing Walls: 1 part cement to 6 or 8 parts sand (less strong for lighter walls).

- Mortar Mix for Reinforced Brickwork: 1 part cement to 3 parts sand.

- Mortar Mix for Plastering in Wet Areas: 1 part cement to 6 parts sand.

- Interior Plastering Mix: 1 part cement to 3 parts sand.

- Exterior Plastering Mix: 1 part cement to 4 parts sand.

- Mixing Weight: The wet mix weighs half as much as the dry mix.

- Bricks per Cubic Meter: 500 bricks for 1 cubic meter of wall.

- Brick Strength: Must handle at least 7.5 N/mm² of pressure.

- Water Absorption for Top-Quality Bricks: Up to 15% of their weight.

- Weight of a Brick: 3.85 kg.

- Fire-Resistant Brickwork: Use fire bricks that resist fire for 3 hours.

- Weight of Cement Bag: 50 kg.

- Density of Cement: 1440 kg per cubic meter.

- Volume of one cement bag: 0.0347 cubic meters.

- Cement bags for one cu.m of concrete: About 28.8 bags.

- Weight of Quarry Sand: 1600 kg per cu.m.

- Weight of River Sand: 1840 kg per cu.m.

- Weight of Coarse Aggregate: 2200 to 2550 kg per cubic meter.

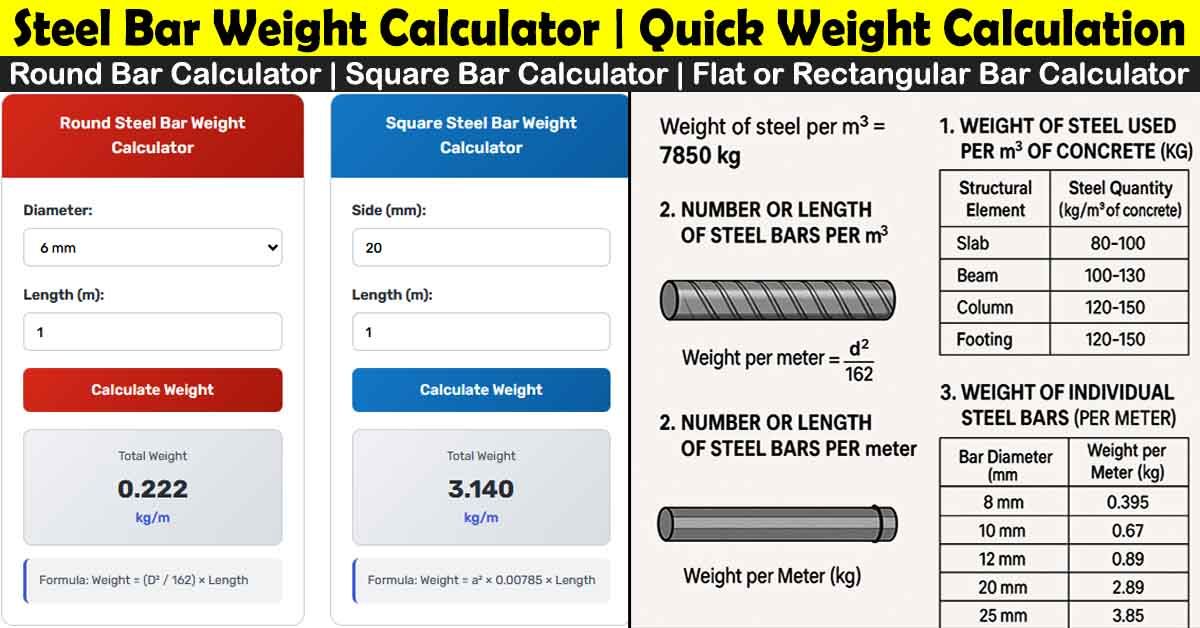

- Weight of Steel: 7850 kg per cubic meter.

- Damp Proof Course Thickness: 25 mm.

Using a 1:3 or 1:4 mortar mix for load-bearing walls makes them strong and durable, especially in damp areas.

Civil Engineering Basic Knowledge for Foundation

When building a strong foundation, Civil Engineering Basic Knowledge ensures that your structure lasts for decades without major issues.

- Steel in Footing: Use steel that’s 0.8% of the concrete’s total volume to make the foundation strong.

- Clear Cover for Steel: Keep 50 mm of concrete around the main bars to protect them.

- Minimum Steel Bar Size: Use at least 10 mm thick bars for the foundation footing.

- Concrete Grade: Use M20 grade concrete or stronger for a solid foundation.

- Foundation Size: Make sure the length, width, and depth are each at least 1 meter.

- Footing Thickness: The footing should be at least 40 cm thick.

- Pile Foundation: If the soil can’t support 24 kN/m³, use a pile foundation for extra stability.

These guidelines help ensure your foundation is strong and reliable!

Loads and Design Considerations

Site works need accurate load calculations. Here’s what to remember:

- Live Load on Residential Buildings: 2.0 kN/m²

- Dead Load of Walls: Varies based on building material, but generally 10-12 kN/m² for masonry

- Wind Load Considerations for High Rise Buildings: According to IS Code 875

- Earthquake Load Design: Seismic Zone Specific

These factors are crucial for safe designs, mainly in high-rise or seismic-prone areas.

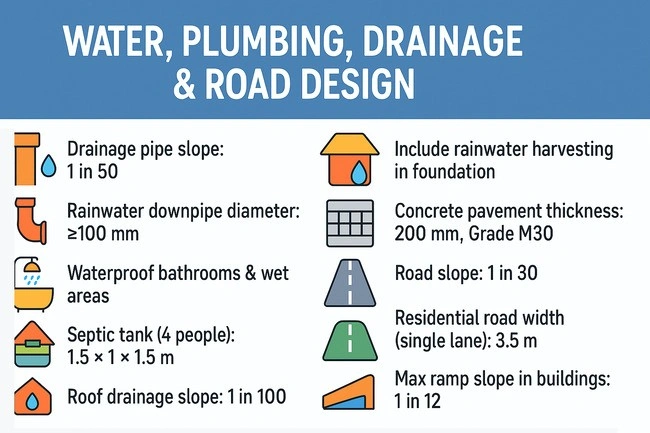

Water, Plumbing, Drainage, and Road Design

Plumbing and drainage are key to a project’s success:

- Minimum Slope for Drainage Pipes: 1 in 50

- Diameter of Rainwater Downpipes: Minimum 100 mm

- Waterproofing Requirement for Bathrooms and Wet Areas

- Min Size for Septic-Tank in a 4-Person Household: 1.5m x 1m x 1.5m (L x W x D)

- Minimum Slope for Roof Drainage: 1:100

- Rainwater Harvesting System: Integration in the foundation planning

- Minimum Thickness for Concrete Pavements: 200 mm

- Minimum Thickness for Concrete Pavements: 200 mm (repeated)

- Grade of Concrete for Pavements: M30

- Recommended Slope for Roads: 1 in 30

- Minimum Width of Residential Road: 3.5 meters for a single lane

- Maximum Slope for providing Ramps in Buildings: 1 in 12

Adding a rainwater harvesting system from the start is wise for sustainable site works.

Requirements for Road and Pavement Designs – Civil Engineers Must Know:

- Among other things, the minimum thickness of concrete pavements is recommended: 200 mm

- Pavement Concrete Grade: M30 Required

- Slope for Roads: 1 in 30

- Residential Road Minimum Width: 3.5 meters for a single lane

- Building Ramps – Maximum gradient 1 in 12

Environmental and Green Building Considerations

In modern construction, it’s important to use methods and materials that are good for the environment. Here are some eco-friendly practices:

- Fly Ash in Concrete: Replace 20–35% of cement with fly ash to save costs and reduce environmental impact.

- Recycled Aggregate: Use up to 20% in non-structural concrete elements.

- Energy-Efficient Windows: Install double-glazed units to reduce heat loss.

- Rainwater Harvesting: Make it a standard feature in all green buildings.

- Solar Panels: Install on rooftops to save energy and reduce power bills.

By using these methods related to Civil Engineering Basic Knowledge, projects become more cost-effective and environmentally friendly.

Conclusion

Civil engineering basic knowledge is key to successful construction projects. Knowing the basics helps ensure projects are completed efficiently and safely. This knowledge is vital for the success of any construction work.

By applying the insights from this guide, civil engineers can improve their skills and handle complex projects with ease. This includes everything from preparing the site to building sustainably.

Learning civil engineering basics is a big step towards better construction. As the construction industry evolves, it’s important for professionals to keep up so they can deliver top-quality projects.

Civil Engineering Basic Knowledge PDF | Download your file

To prevent abuse, the pdf download file will unlock after a short countdown.

FAQs

You can find answers to the most common questions related to the Civil Engineering Basic Knowledge.

What are the key skills of a site engineer?

Key skills include strong communication for working with stakeholders. They also need to make decisions quickly to solve problems on-site. They must be proficient in civil engineering software like AutoCAD.

Leadership skills are crucial for managing a team. They also need to know construction regulations and safety protocols well.

What is the basic knowledge of civil engineering drawing?

Understanding different types of drawings is key. This includes plans, elevations, and sections. Knowing about orthographic projections, symbols, and scales is also important.

They must know how to dimension drawings correctly. This ensures accurate site implementation of construction blueprints.

What are the standards for civil engineering?

Involved in promoting safety, reliability and efficiency are standards such as ASCE guidelines on structures, ASTM on testing materials, ISO on quality management and codes such as IS 456 on concrete in India or IBC on building in the US.

What is the basic knowledge of a civil site supervisor?

Simple project skills are the ability to plan and coordinate, knowledge of construction laws, rules and regulations regarding safety, cost estimation, leadership to supervise the team and technical skills in the monitoring of progress and quality assurance.

What are the Basics of Civil Engineering?

Fundamentals include structural engineering, material science and technology (such as concrete, steel), geotechnical engineering on foundations, surveying, hydraulics on water systems, and sustainable design concepts of infrastructure such as roads and buildings are the civil engineering basics.

Quite detailed. 👍

Thanks for your comments. Please get in touch for more knowledge.

Hi

I m Shakeel and i appriciate you to share this basic knowledge for all related persons

So thanks

Thanks for your comments. Please get in touch for more knowledge.

I Realy Like This Website So concept clear methods of construction works

Thanks for your comments. Please get in touch for more knowledge.