Last updated on: October 30, 2024

Did you know that the right Development Length can determine whether a building is safe or not It is important to guarantee that beams, columns and footings are designed for loads. Today in this post, we cover how the development of reinforcement is influenced and calculated for your projects.

Before reading this article you must know about the following:

Reinforced Concrete Basics

Reinforced concrete is a key building material. It mixes the strength of reinforced bars (also known as rebar) with concrete‘s flexibility. This mix is vital for making strong and lasting buildings, bridges, and more. Knowing how reinforcement works in concrete is key to keeping these structures safe and lasting.

Understanding Reinforcement in Concrete

Reinforcing bars in concrete add tensile strength, which concrete can’t provide on its own. These deformed bars, usually made of steel, help resist forces on the structure. The bond between concrete and reinforcement bars helps distribute loads well, boosting the structure’s performance.

What is development length?

The concept of development length is key in reinforced concrete design. It’s the minimum bar length needed in concrete to reach its full strength. This length is vital for stress transfer between concrete and reinforcement, ensuring the structure’s integrity.

The development-length of rebar is key for the safety and strength of concrete structures. Here are some important points:

- Bond Strength: It makes sure the rebar and concrete bond well, stopping slippage and failures.

- Tensile Stress Transfer: The right development length lets the rebar share its strength with the concrete. This is vital for handling loads and keeping things stable.

- Preventing Pullout Failures: Without enough development length, the rebar might pull out under stress. This could cause big failures.

- Compliance with Standards: Following development length rules helps meet engineering standards and building codes. This promotes safe building practices.

- Durability: The right development-length helps the structure last longer. It makes sure the rebar stays well anchored in the concrete.

Rebar Development Length Formula

The reinforced concrete design relies on the development-length of rebar. This formula is used to determine the length in accordance with IS and ACI methods.

Development Length formula as per IS (456:2000):

The formula as per IS Code 456:2000 (Clause 26.2.1) is:

Ld = ( ϕ ⋅ σs ) / ( 4 ⋅ τbd )

Where:

- Ld = Development-length (in mm)

- ϕ = Nominal diameter of the bar (in mm)

- σs = Stress in the bar at the section considered under design load (in MPa)

- τbd = Design bond stress (in MPa) between the concrete and the steel, which varies based on factors like concrete strength and bar type

Key Points to Consider:

- Bond Strength: Depends on concrete compressive strength, the type of reinforcement used and environmental conditions.

- Anchorage Values: Account for hooks in tension reinforcement.

- Reduction Factors: Excess reinforcement allows for reduced Ld based on steel area ratio.

- Minimum Development Length: The minimum development length for bars in tension is 41 times the diameter of the bar (41Φ) and for bars in compression is 21Φ

Development Length formula as per ACI (318-14):

As per ACI 318-11 , the development-length of reinforcing bars is crucial for ensuring that the bars can develop their full yield strength within the concrete.

Tension Development Length

- Basic Equation:

The basic tension development-length (Ld) is calculated using formula:

d = ( fy ⋅ Ldb ) / ( ϕ ⋅ √fc′ )

Where:- fy = Yield strength of the steel (in psi)

- Ldb = Diameter of the bar (in inches)

- ϕ = Reinforcement location factor

- fc′ = Compressive strength of concrete (in psi)

- Simplified Equation:

The simplified method calculates Ld but is less conservative. Straight bars need a minimum of 300 mm (12 inches).

Compression Development Length

For bars in compression, the development-length is shorter due to bearing stresses at the end of the bar transferring some force into the concrete. The basic compression development length is calculated similarly but with a minimum requirement of 200 mm (8 inches).

Modification Factors

- For epoxy-coated bars, a modification factor is applied, typically increasing the required development length.

- Increase development lengths for bundled bars by specific factors (1.2 for three-bar bundles and 1.33 for four- bar bundles) to account for the reduced effective perimeter for bond failure.

Minimum Development Length Requirements

- The minimum tension development length is set at 300 mm (8 inch).

- The minimum compression development length is set at 200 mm (12 inch).

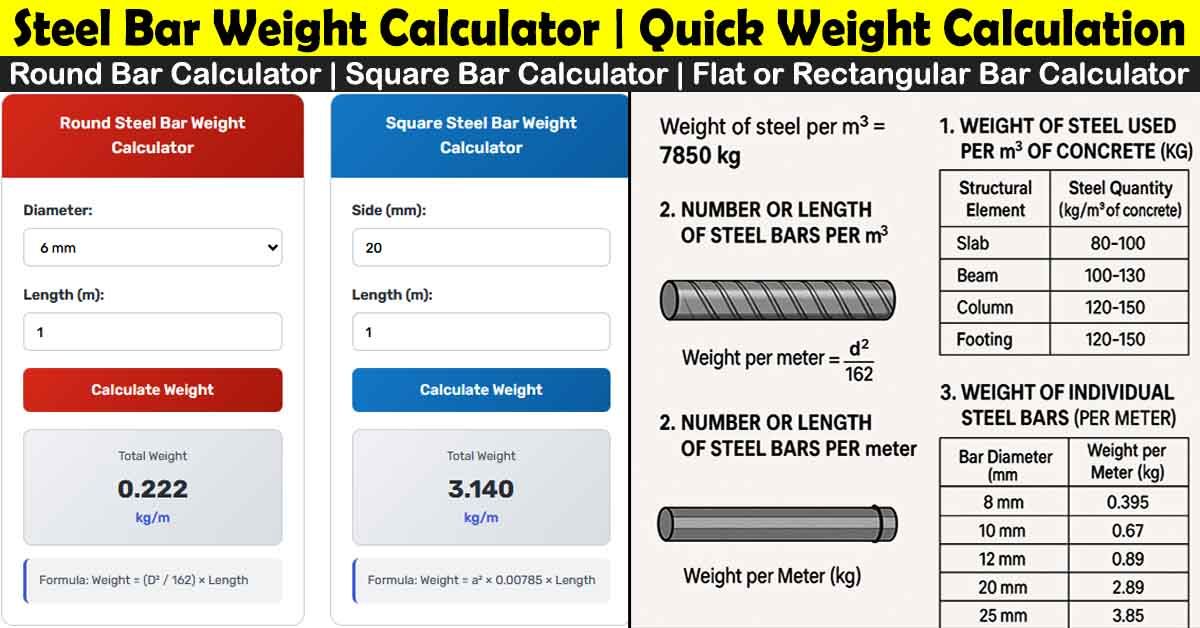

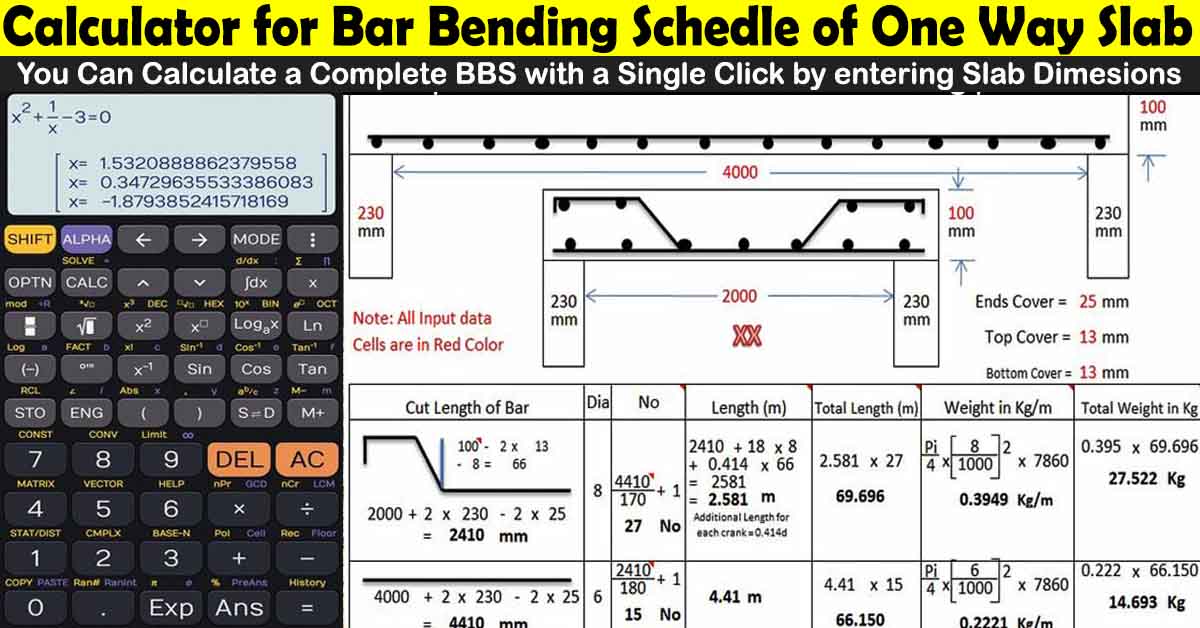

Read More about: Steel Weight Calculator for One Way Slab

How to Calculate Development Length of Rebar

Let’s calculate the development-length for a 10 mm diameter rebar in M25 concrete, where the stress in the bar at the design load is 30 MPa.

Step 1: Identify Parameters

- Diameter (ϕ) = 10 mm

- Stress (σs) = 30 MPa

- Design bond stress (τbd) for M25 concrete = 1.4 MPa

Step 2: Substitute Values into Formula

Now, substitute these values into the formula:

Ld = ( 10 ⋅ 30 ) / ( 4 ⋅ 1.4 )

Step 3: Calculate

Calculating this gives:

Ld = 300 / 5.6 = 53.57 mm

Step 4: Quick Estimation

Ld ≈ 41 × ϕ = 41 X 10 = 410 mmIn this case, use the higher value from precise calculations to ensure safety

Thus, the Ld required for a 10 mm diameter rebar under these conditions is approximately 410 mm.

Factors Effecting on Development Length of Rebar:

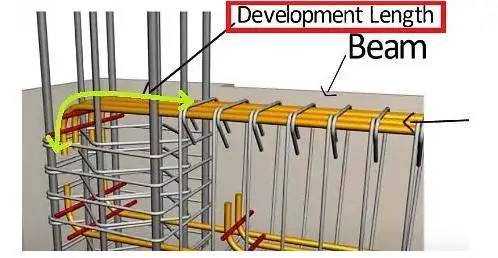

Development Length in Beam-Column and Footing

Development-length is key in reinforced concrete design, especially in beam-column and footing connections. It makes sure the reinforcing bars (rebars) can carry loads to the concrete without slipping.

Development Length in Beam-Column Connections

In beam-column joints, the bar’s development-length is vital for structural strength. It lets the main bars in the concrete beam reach into the column.

This ensures stresses are safely passed from the beam to the column. The length needed must be enough to fully use the rebar’s strength in concrete.

Development Length in Footings

In footing development-length for Reinforcement is also an important factor, as it provides the possibility that rebars are efficiently able to transfer loads from column to footing. It depends on the bending moments that any applied loads generate and how far away from the column face you get to an edge of a footing.

Key Considerations

- Critical Section: The length for development is measured from the column face to the footing edge, minus any concrete cover.

- Bond Strength: Better bond strength between concrete means shorter Ld’s are possible.

- Rebar Size: Bigger diameter bars need longer development-lengths because they carry more load.

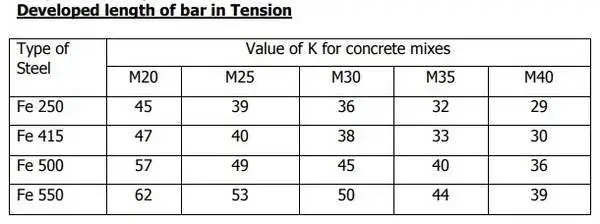

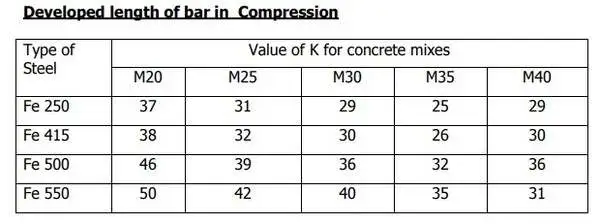

Development Length Table for Tension and Compression Bars

Following are the Development-Length of bars for different steel type and different concrete mixes:

Ld = k ϕ

where k is based on character strength of steel, concrete bond stress. The constant k value for various type of steel and concrete for Tension & compression are given below for reference.

Conclusion:

This article covers the key concepts of development length in reinforced concrete, from reinforcement basics to the factors that affect it. Understanding ACI code guidelines and how to calculate development length for beams, columns, and footings is essential for creating strong, durable structures. Following these rules ensures that buildings and other structures are safe and long-lasting.

FAQs:

What is the Differences Between Development Length and Lap Length

| Aspect | Development Length | Lap Length |

|---|---|---|

| Purpose | Connects steel reinforcement to concrete | Joins two steel bars for continuity |

| Force Type | Does not carry tension forces | Carries tension forces |

| Minimum Length | Generally 41 times bar diameter (41d) | Ranges from 24d to 55d depending on application |

What is the Difference between Anchorage Length and Development Length?

| Feature | Development Length | Anchorage Length |

|---|---|---|

| Purpose | To ensure that the rebar can transfer loads to concrete without slippage. | To develop stress in the rebar when sufficient development-length cannot be provided. |

| Application | Used in flexural and axial tension/compression scenarios. | Typically applied at supports or fixed ends where bars are bent or hooked. |

| Calculation Basis | Calculated based on factors like bar diameter, yield strength, and bond stress. | Often considered as a fixed multiple of the bar diameter (e.g., 8 times for a 90° bend). |

| Length Requirement | Minimum development length is generally set at 41 times the bar diameter (41Φ). | Anchorage length can vary but is often specified as a multiple of the bar diameter (e.g., 8Φ for a 90° bend). |

What is development length in structural engineering?

Development-length is the minimum length of a reinforcing bar (rebar) that must be embedded or anchored into concrete. This ensures that the rebar and concrete bond properly. They work together to resist forces.

This is important because it prevents the rebar from slipping out of the concrete under tension or stress.

How the Calculation of Development Length performed?

Calculations follow the ACI 318 building code. They consider tension, compression, and splitting to figure out the needed reinforcement length.

Why is Providing Development Length necessary?

It’s crucial for the reinforcement to work with the concrete. Without enough length, the reinforcement might fail early. This could harm the structure’s strength.

What is the formula for developed length?

you can see in above article

How is development length calculated?

Development-length is calculated using a formula that considers factors such as the type of rebar, its diameter, the strength of the concrete, and whether the bar is coated with epoxy. The formula is typically found in design codes like the ACI (American Concrete Institute) standards and looks something like this:

Ld = ( ϕ ⋅ fy ) / (4 ⋅ τbd )

where:

Ld is the development-length,

ϕ is a factor based on the type of steel,

fy is the yield strength of the steel, and

τbd is the bond stress.

Hi dear please send me my whatsapp no +923004543179

you can ask here

want know the spacing of bar for PCC with the size of 46′ x 38′. also know the dia of the bar which we can used

Thanks for your comments. Please get in touch for more knowledge. I will upload more construction and BBS calculators soon