Table of Contents

Bar Bending Schedule (BBS) – A Step-by-Step Guide for Beginners

Do you want to start bar bending? Then this article is for you. In this article, we’ll explain what rebar bar bending schedule (BBS) is and how it can help newbies learn the skill quickly about bbs format. A bar bending schedule (BBS) is a detailed list of the rebar required for a construction project. It is prepared by a civil engineer or rebar detailer and provides instructions for the fabrication and installation of the steel bar reinforcement. The BBS format is an essential part of the reinforced concrete design process.

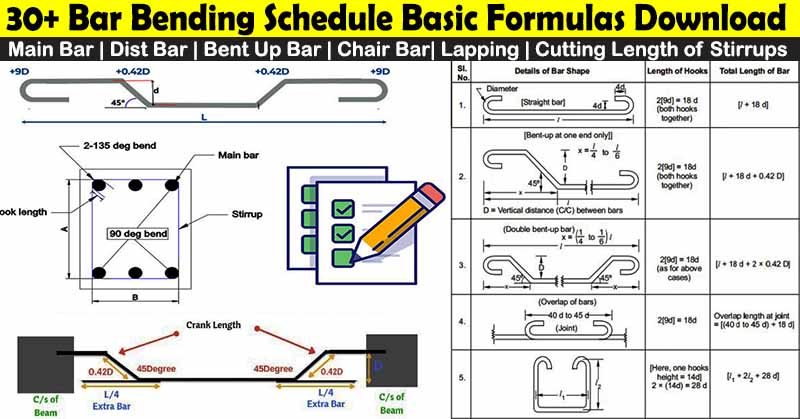

Before reading this article you must read this Bar Bending Schedule Formulas

What is Bar Bending Schedule?

A bar bending schedule is a detailed list of the lengths and shapes of bars, as well as the location, size, number, and quantity of each bar, that are needed for a construction project. It is typically used in the construction of reinforced concrete structures, such as building foundations, columns, beams, and slabs.

The schedule is typically prepared by a structural engineer or a contractor and is used by the steel reinforcement workers to ensure that the correct amount and type of reinforcing bars are placed in the correct locations in the concrete.

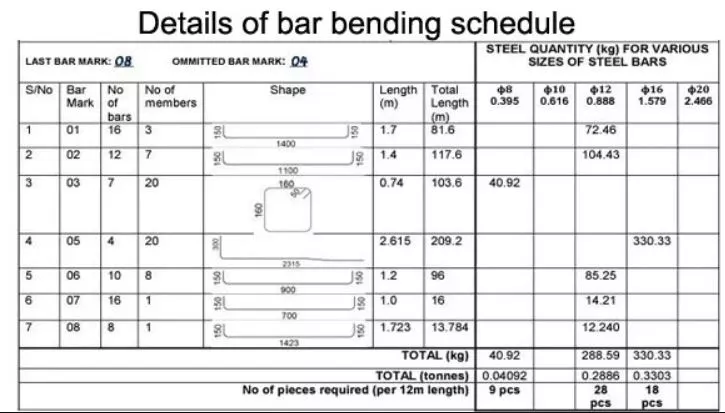

Bar Bending Schedule Format:

A bar bending schedule format typically consists of a table with rows and columns. The rows represent individual bars or groups of bars, and the columns contain information about the size, shape, length, and other specifications of the bar(s).

Some examples of columns that may be included in a bar bending schedule (steel bending schedule) table are:

- Bar number: A unique identifier for each bar or group of bars.

- Shape: The shape of the bar, such as circular or square.

- Size: The diameter or width of the bar.

- Bar Cutting Length: The bar cutting length is a length of a rebar (reinforcing bar) that needs to be cut and bent to the specified shape and dimensions. This can be find by using bar bending schedule formulas.

- Total Length: The total length of the rebar, including cutting length or any additional length needed for overlap or for projecting beyond the end of the concrete element.

- Quantity: The number of bars in each group.

- Weight: The weight of each bar or group of bars.

- Bending radius: The required radius for any necessary bends in the bar.

- Location: The location of the bar within the structure, such as “foundation” or “beam.”

- Purpose: The purpose of the bar, such as providing structural support or reinforcing a specific area.

- Notes: Any additional information or comments about the bar or its placement in the structure.

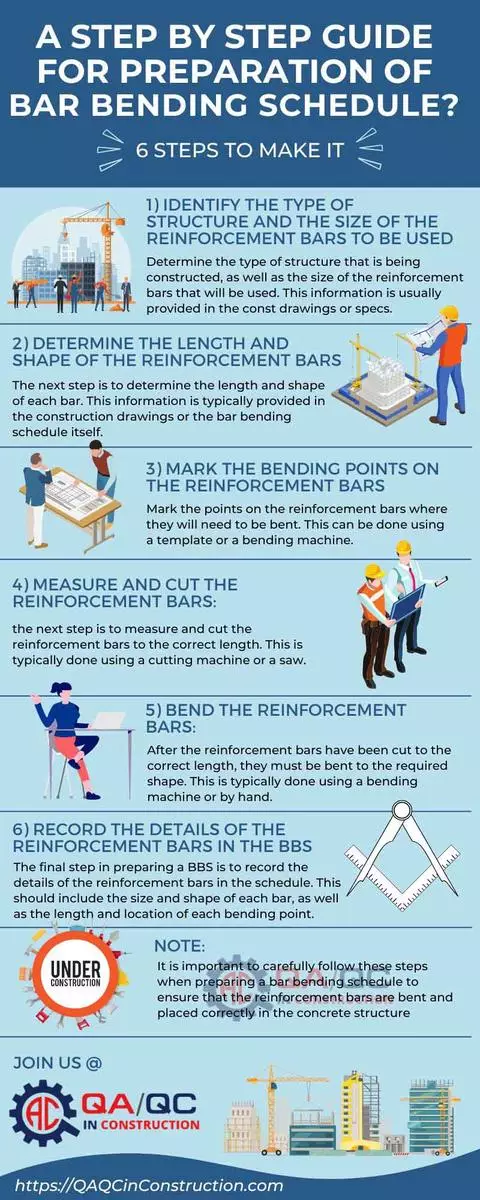

How to Prepare Bar Bending Schedule:

To preparation of bar bending schedule or reinforcement bending schedule, follow these steps:

- Obtain a copy of the construction drawings, including the reinforced concrete detailing drawings.

- Identify all the reinforced concrete elements in the construction, such as beams, columns, foundations, and slabs.

- Determine the size and shape of the rebar required for each element, based on the design requirements and the construction drawings.

- Calculate the total length of rebar needed for each element, taking into account the length of the element, the spacing of the rebar, and any additional length needed for overlap or for projecting beyond the end of the element.

- Prepare a table or spreadsheet (bar bending schedule format) listing the rebar size, shape, and total length for each element.

- Review the schedule with the structural engineer or project manager to ensure that it is complete and accurate.

- Provide a copy of the schedule to the rebar fabricator and the construction crew.

It is important to note that the preparation of a bar bending schedule requires a thorough understanding of structural design principles, as well as the ability to read and interpret construction drawings.

Terms to Describe the Different types of Rebars in BBS:

In BBS Civil, the following terms are often used to describe the different types of rebar (reinforcing bars) that may be used in a construction works project:

Main bar:

This refers to the rebar that is used to provide the primary reinforcement in a concrete element, such as a beam or a column. The main bar is typically the largest and strongest rebar in the element, and it is used to carry the majority of the load.

Distribution bar:

This refers to smaller rebar that is used to distribute the load from the main bar to the concrete.

Distribution bars are typically used in conjunction with main bars, and they are often spaced at regular intervals along the length of the main bar.

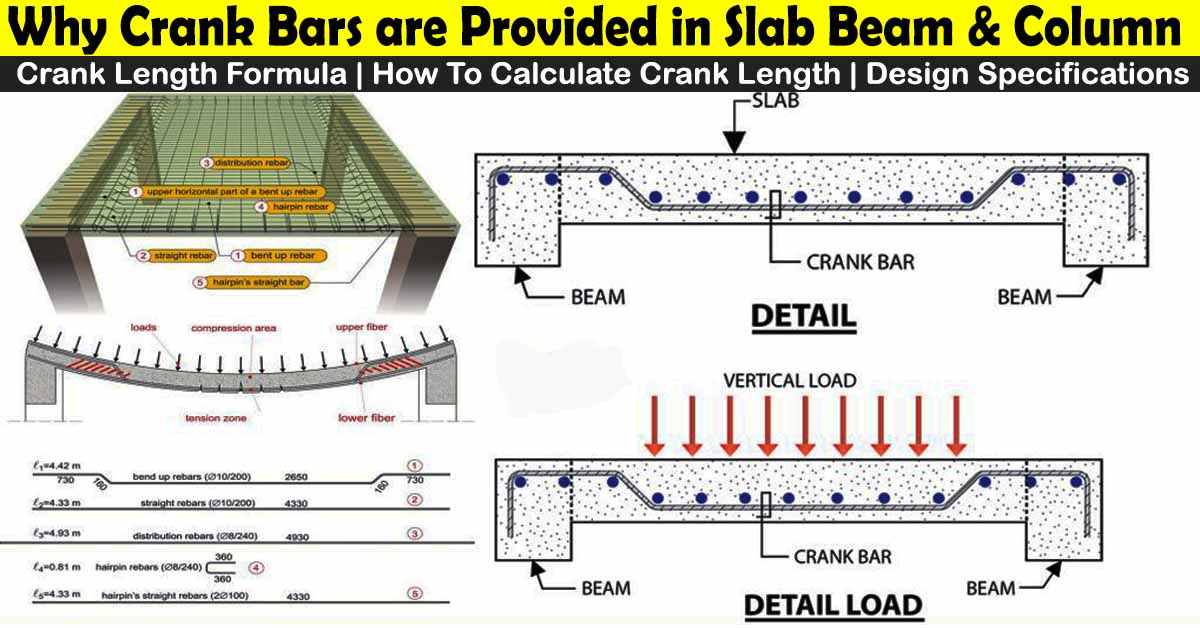

Bent-up bar:

This refers to rebar that is bent at an angle and anchored to the concrete. Bent-up bars are often used to provide additional reinforcement at the ends of beams or at points of high stress in the element.

Stirrups:

These are small rebar that is used to provide lateral support to the main bars. Stirrups are typically bent into a circular or square shape, and they are placed at regular intervals along the length of the main bars.

Extra bars:

These are additional rebar that may be required at certain locations in the element, such as at points of high stress or at the ends of the element.

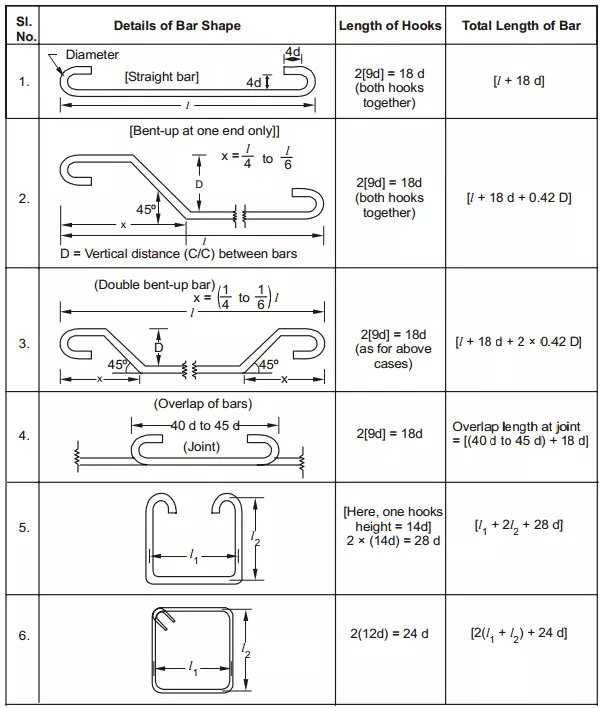

Standard hooks:

These are bent ends on the rebar that are used to anchor the rebar to the concrete. Standard hooks are typically specified in the design drawings or in the construction specifications, and they must be included in the bar bending schedule.

Helical bars:

These are rebar that is twisted into a spiral shape, and they are used to provide additional reinforcement to the concrete element specially in columns.

Anchor bar:

This refers to rebar that is used to anchor the ends of other rebars in the element. Anchor bars are typically used to provide additional reinforcement at the ends of beams or at points of high stress in the element.

Bar Bending Schedule Formulas:

Advantages of Bar Bending Schedule:

There are several advantages to using a bar bending schedule in construction projects:

It helps:

- To ensure that the correct amount and type of reinforcing bars are used in the construction, which is important for maintaining the structural integrity of the building.

- To reduce waste by ensuring that the correct amount of reinforcing bars are ordered and used.

- To improve the efficiency of the construction process by providing a clear and detailed plan for the placement of reinforcing bars.

- To improve communication between different members of the construction team by providing a clear and detailed plan for the placement of reinforcing bars.

- To minimize the risk of errors and mistakes during the construction process by providing a clear and detailed plan for the placement of reinforcing bars.

Types of Steel Reinforcement used in Construction Projects:

There are several types of steel reinforcement bars but the following three are mostly used in structural construction works:

FE-250:

Bars have a yield strength of 250 MPa (megapascals). They are commonly used in low-rise buildings and other structures with low loading requirements.

FE-415:

Bars have a yield strength of 415 MPa. They are used in medium-rise buildings and other structures with moderate loading requirements.

FE-500:

Bars have a yield strength of 500 MPa. They are used in high-rise buildings and other structures with high loading requirements.

Notations in Reinforcement (Steel Bars) Detailing:

Reinforcement detailing is the process of designing and specifying the reinforcement for a concrete structure. In this process, various notations are used to represent the size, shape, and location of the reinforcement bar. Some common notations used in reinforcement detailing are:

Bar size:

The diameter of the bar is typically represented by the size of the bar in millimeters, such as “16mm” or “20mm.”

Shape:

The shape of the bar can be represented by a letter, such as “R” for round bars or “S” for square bars.

Location:

The location of the bar within the structure can be represented by a letter or symbol, such as “T” for top or “B” for bottom.

Spacing:

The distance between adjacent bars can be represented by a number or symbol, such as “100mm” or “c/c” (center to center).

Cover:

The cover of the reinforcement bars refers to the distance between the surface of the concrete and the top of the bars. This is typically indicated in “mm”.

Bending Radius:

The required radius for any necessary bends in the bar can be represented by a number or symbol, such as “r=100mm” or “R=2d.”

Length:

The length of the bar can be represented by a number, such as “500mm” or “1000mm.”

Quantity:

The number of bars in each group can be represented by a number, such as “2” or “4.”

Direction:

The direction of the bar can be represented by a letter or symbol, such as “L” for longitudinally or “T” for transversely. sometime “T1” for outer layer and “T2” for second layer

Orientation:

The orientation of the bar can be represented by a letter or symbol, such as “V” for vertical or “H” for horizontal.

Conclusion:

In conclusion, preparing a rebar bar bending schedule is a crucial step in any construction project. By following the steps outlined in this post and using the appropriate tools and resources, you can ensure that your bar bending details is accurate and effective. Remember to double-check all measurements and calculations, and use software to streamline the process if possible.

OTHER POSTS:

- 30+ Bar Bending Schedule Formulas | BBS Steel Calculation

- Method Statement for Cutting and Patching Works

- Method Statement for Cast in Place Concrete Works

- Method Statement for Bituminous Damp Proofing for Concrete and Masonry

- Method Statement for Trench Excavation and Backfill for Electrical Cables

FAQs:

What does BBS stand for in construction?

BBS stands for Bar Bending Schedule in construction.

What is LD in bar bending schedule?

In a bar bending schedule, the “LD” (development length) refers to the length of rebar that must be embedded in the concrete in order to develop the full strength of the rebar. The development length is typically required when the rebar is being anchored into the concrete, such as when it is being anchored at the end of a beam or when it is being anchored to a column or wall.

IS code for steel Bar Bending Schedule?

The Indian Standard (IS) code for the preparation of steel bar bending schedules is IS 2502:1959

Who Prepare bar bending schedule?

A bar bending schedule or rebar bending schedule is typically prepared by a structural engineer or a rebar detailer.

Why Steel Reinforcement used in RCC structures?

Steel reinforcement is used in reinforced concrete (RCC) structures to improve their strength and ductility. Concrete is a strong and durable material, but it is brittle and does not have much tensile strength. Steel, on the other hand, is strong in both tension and compression, and it has good ductility (the ability to deform without breaking).

What is Cutting Length in Bar Bending Schedule?

Cutting length is the length of a reinforcement bar after it has been cut to size and bent to the required shape.

Magnificent

Thanks for comment, For more related posts please visit Civil, Arch, Electrical and Mechanical Tab in File menu