Last updated on: March 25, 2023

Thumb Rules for Civil Engineering & Quantity Surveyors Formulas

Any civil engineer, site engineer, or civil supervisor must be familiar with Thumb Rules for Civil Engineering. They are essential when making prompt decisions on the site. Every civil engineer needs to be familiar with the Civil Engineering Basic Knowledge.

The Thumb Rules of Civil Engineering, often known as the thumb rule for building construction, assists you in solving problems utilizing a straightforward mathematical formula and in arriving at wise conclusions when necessary.

However, it’s important to keep in mind that utilizing a thumb rule only produces approximations; it never provides exact or accurate outcomes.

In construction work, we applied a number of thumb rule for civil engineers. The following are some of the thumb rules that are most frequently employed on construction sites.

Thumb Rule for Concrete Work or Concrete Volume:

“28 days strength is the characteristic strength of the concrete” – This thumb rule is used to determine the concrete strength after 28 days of curing.

“One-fourth of the concrete section should have steel reinforcement” – This rule-of-thumb is used to estimate how much steel reinforcement is required in a concrete slab or foundation

“Excavation depth should be 1.5 times the width of the foundation” – This rule of thumb is used to establish the proper excavation depth for a building project based on the width of the foundation

“Water-cement ratio should be 0.5” – This thumb rule is used to establish the ratio of water to cement in the concrete mix, which is important for the durability and strength of concrete.

“A single layer of vibrator for every 12 feet” – This thumb rule is used to determine the number of vibrators needed for a concrete pour, which helps to eliminate air bubbles and ensure a smooth finish.

“A slump test should be performed before pouring the concrete” – This rule of thumb is used to assess the consistency of the concrete mix, which is crucial for the appropriate curing and strength of the concrete

“volume of concrete required = 0.038 m3 /square feet area” – For Example: If Plan Area is 40 x 20 or 800 square meters.

Therefore, the total amount of concrete needed for the 800 sq. m. design area is

= 800 x 0.038m3 = 30.4m3

Thumb Rules for Slab:

- The minimum thickness of slab should be 125mm.

- The minimum diameter of bars used in slab should be 8mm.

- Fe 500 Steel should be used in the RCC slab.

- A clear cover of 15mm to 20mm should be provided in RCC slab.

- Maximum diameter of bars used in RCC slab is 1/8th times of slab thickness.

- Steel required in the RCC slab is 1% of the total volume of concrete.

- M15 Grade of concrete or above it should be used in RCC slab.

- Spacing between reinforcement in the RCC slab should not be less than 150mm c/c.

Thumb Rules for Beam:

- Steel required in the RCC beam is 2% of the total volume of concrete.

- A minimum clear cover of 40mm shall be provided in beams.

- M15 Grade of concrete or above it should be used in the RCC slab.

- Spacing between reinforcement in the RCC slab should not be less than 150mm c/c.

- M20 grade of concrete should be used in RCC beam construction.

- Minimum 4 bars shall be provided in reinforced concrete beams. 2 bars of 12mm at top and 2 bars of 10mm at the bottom.

Thumb Rules for Column:

- Spacing between Longitudinal steel reinforcement should not be more than 300mm.

- Minimum clear cover in RCC column is 40mm. 25mm clear cover is provided if column is less than 200mm.

- M20 Grade of concrete is used in concreting column.

- Fe 500 Steel is also recommended for rcc column reinforcement.

- A Column should be equally spaced in a grid so as to efficiently transfer the load.

- The minimum dia of 12mm bars 4 numbers should be used in column.

- The maximum dia of reinforcing bars in the column should be not more than 50mm.

- The Overlapping distance in longitudinal bars should not be less than 24 times the smallest bar dia.

- The maximum spacing of stirrups is 16D or B or 300mm whichever is less.

- The steel required in the Column is 2.5% of the total volume of concrete.

- Minimum steel requirement in column = 0.8% of the gross area of concrete

- Maximum steel requirement in column = 6% of the gross area of concrete

- The minimum size of column should not less then 9″ X 9″.

- For G+1 Structure 9″ X 12″ (225mm X 300mm) RCC Column should be used.

- The maximum space between two columns of size 9″ X 9″ should not be more than 4 meter.

Thumb Rules for Foundation:

- Steel required in rcc footing is 0.8% of total volume of concrete

- The clear cover of main reinforcement in footing should be 50mm.

- A minimum 10mm bar shall be used for foundation footing.

- M20 grade of concrete or above is used for foundation.

- Length, width and depth of foundation should not be less than one meter.

- A Footing thickness should not be less then 40 cm.

- The Pile foundation should be used if soil bearing capacity is less than 24 kN/m3.

Thumb Rules for Building Estimation:

Calculate Steel Reinforcement for Slab, Beams, Footings & Columns:

Here are some crucial general guidelines for calculating the steel needed for footings, beams, slabs, and columns.

Steel Reinforcement required in residential buildings = 4.5 Kgs – 4.75 Kgs / sq. Ft.

Steel Reinforcement required For Commercial buildings = 5.0 Kgs-5.50 Kgs/Sq. Ft.

You can also use B-N Datta recommendations for the more accurate result,

The following recommendations Thumb Rules For Civil Engineering are given in B-N Datta for the Steel quantity used in different members of the building.

Percentage of Steel Quantity in Structural Members:

The following are general guidelines for concrete member reinforcing:

- Slab – 1% of the total volume of concrete (Slab steel calculation thumb rule).

- Beam – 2% of the total volume of concrete.

- Column – 2.5% of total volume of concrete.

- Footings – 0.8% of the total volume of concrete.

Thumb Rule For Shuttering Work:

Shuttering expenses are calculated at 15–18% of the building’s overall construction costs. To shape the concrete, shuttering work is done. The rule of thumb for calculating the amount of shuttering needed is 6 times the amount of concrete or 2.4 times the area of the plinth.

For example, If the concrete quantity is 0.5m3, then

Area of Shuttering = 0.5 x 6 = 3m2

Components of Shuttering:-

The Shuttering plate Ply, Battens and Nails are components of Shuttering.

Shuttering Ply Quantity estimation:

Suppose, The shuttering Ply has a length, width and depth of 2.44 x 1.22 x 0.012

The Number of Shuttering Ply sheets = 0.22 times of Shuttering

Suppose, the shuttering area = 3m

Then Ply required for shuttering = 0.22 x 3 = 0.66m2

Battens Quantity Calculation:

Shuttering batten usually has a length & width of 75mm x 40mm.

Batten Quantity = 19.82 x No. of Ply Sheets

If work requires 25 Ply sheets, the total quantity of Battens are 19.82 x 25 = 495 Battens

Nails & Binding Wire Quantity Calculation in Shuttering:

Approximately, 75 gms of Nails used in the shuttering of the 1m2 area.

75gms of Binding wire is used for every 1m2 of Shuttering.

Thumb rule for Shuttering oil estimation :

Shuttering oil is applied on the shuttering plate surface used to de-frame or de-assemble from the concrete easily.

Total required Shuttering oil = 0.065 x Total Area of Shuttering

(or)

For every 15m2 of shuttering 1 liter of shuttering oil is consumed.

Example :

If, total area of shuttering is 15 m2, then Shuttering oil Consumption = 0.065 x 15 = 0.975.

Thumb Rules For Civil Engineers for Brickwork:

The following are general guidelines for calculating cement and brickwork calculation in civil engineering.

| Brickwork for 1m3 | Cement Qty in m3 | Cement Qty in Bags |

| 230 mm Brickwork | 0.876m3 | 25.4 Bags |

| 115 mm Brickwork | 0.218m3 | 6.32 Bags |

Thumb Rule For Cement Masonry Quantity:

| Cement Masonry Type & Mix | Cement Qty in Bags | Cement Qty in Kgs |

| 200mm in Cement Masonry work of Ratio 1:6 |

0.124Bags/m2 | 6.2Kgs/m2 |

| 150mm in Cement Masonry work of Ratio 1:6 |

0.093Bags/m2 | 4.65Kgs/m2 |

| 200mm in Cement Masonry work of Ratio 1:4 |

0.206Bags/m2 | 10.3Kgs/m2 |

| 150mm in Cement Masonry work of Ratio 1:4 |

0.144Bags/m2 | 7.2Kgs/m2 |

| 100mm in Cement Masonry work of Ratio 1:4 |

0.103Bags/m2 | 5.15Kgs/m2 |

Thumb Rule Plastering Work:

| Type of Plastering | Cement Qty in Bags | Cement Qty in Kgs |

| Rough Plastering work | 0.09 Bags/m2 | 4. 5Kgs/m2 |

| Internal Wall Plastering work | 0.09 Bags/m2 | 4.5 Kgs/m2 |

| Duct Plastering work | 0.09 Bags/m2 | 4.5 Kgs/m2 |

| External Wall plastering work | 0.175 Bags/m2 | 8.75 Kgs/m2 |

| Stucco Plastering work | 0.175 Bags/m2 | 8.75 Kgs/m2 |

| Lathen Plastering work | 0.55 Bags/m2 | 27.5 Kgs/m2 |

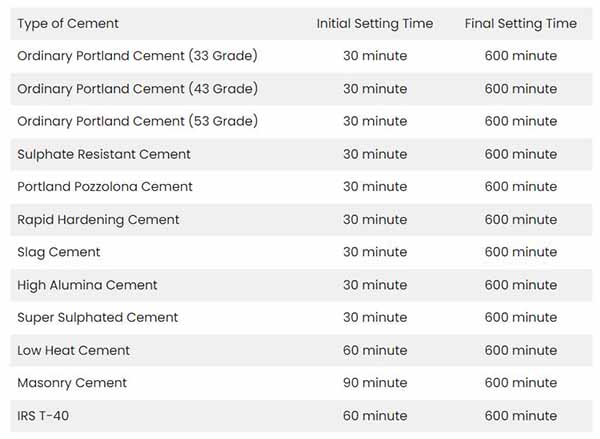

Setting Time of Cement:

The cement hardens when it is mixed with water. But how much time is required for the setting of cement depends upon the type and grade of cement.

There are two setting times, they are

- Initial setting time of cement

- Final Setting Time of Cement

Initial Setting Time of Cement:

When water is introduced to cement paste, the cement paste begins to lose its fluidity. This is known as the initial setting period of cement.

As we all know, cement begins to build up after adding water. The initial setting time of cement is the period of time that passes following the addition of water and the loss of cement fluidity.

Initial setting time is measured with the help of Vicat Apparatus. Generally, the initial setting time of cement is 30 (thirty) minutes.

Final Setting Time of Cement:

The final setting time of cement is the interval of time between the first water addition and the point at which the cement has entirely lost its fluidity.

For all types of cement, the final setting time is 600 seconds.

The initial and final setting times of each type of cement are listed below.

OTHER POSTS:

-

Deflection Angle in Surveying – How to Calculate and Measure

-

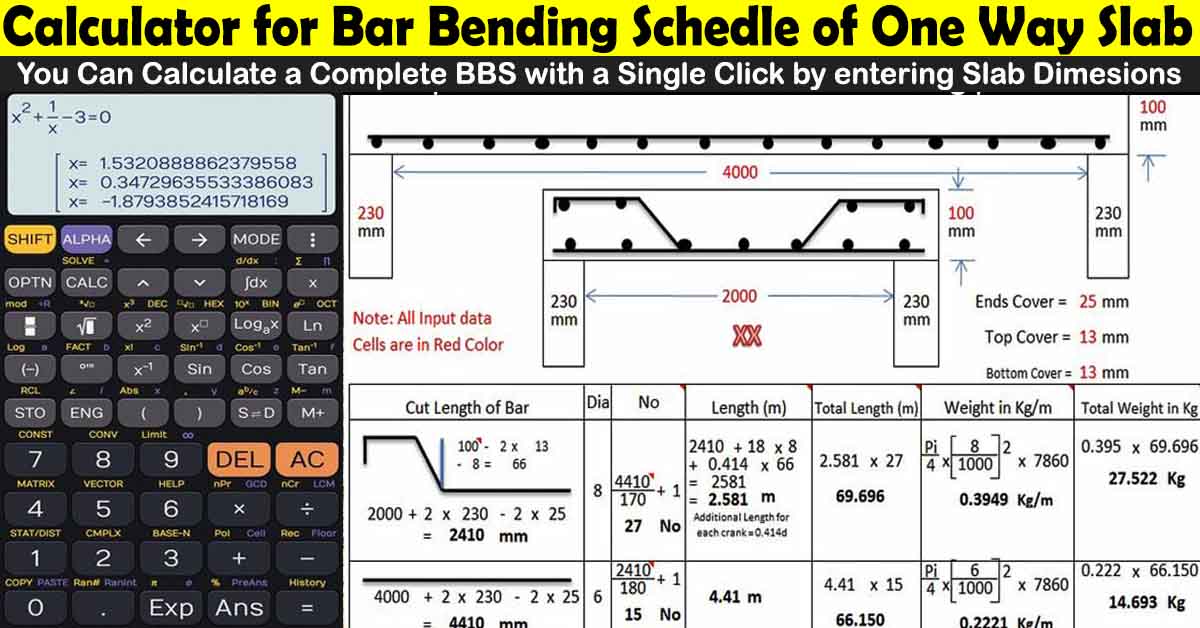

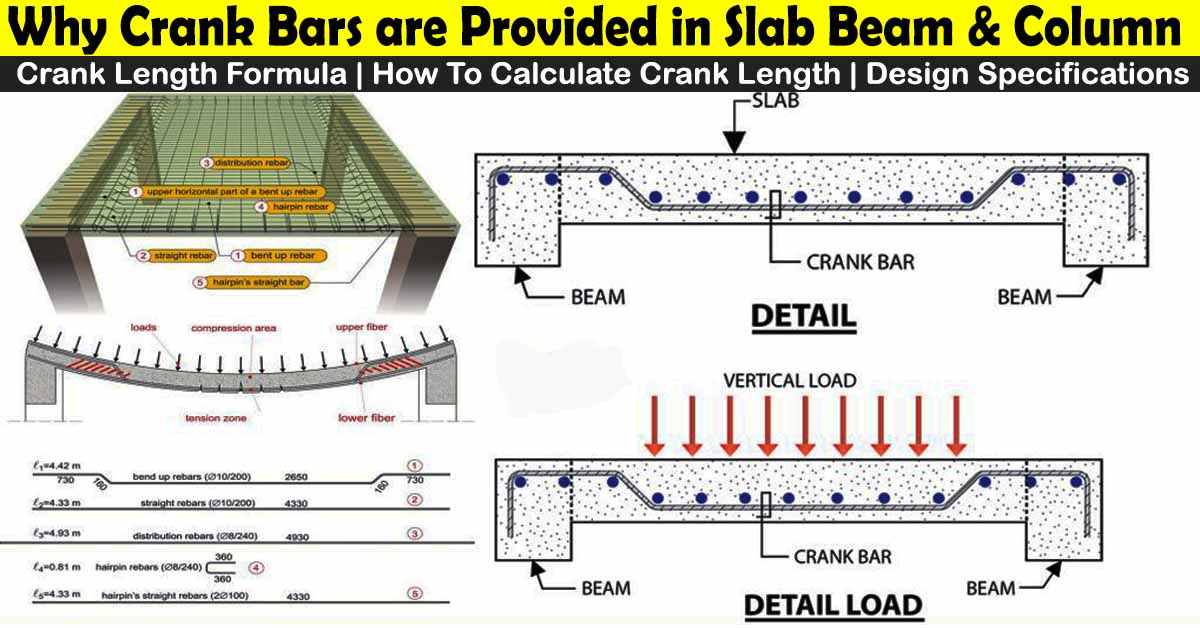

Bar Bending Schedule – A Step-by-Step Guide for Rebars BBS

-

30+ Bar Bending Schedule Formulas | BBS Steel Calculation

-

Method Statement for Trench Excavation and Backfill for Electrical Cables

- Can You Lay Asphalt In Winter

FAQs:

What is the Basic Knowledge of Civil Engineering?

– Lapping in steel reinforcement is not allowed for the bars having diameters more than 36 mm.

– Steel Chair maximum spacing is 1.00 m (or) 1 No per 1m2.

– In steel dowels, a rod minimum of 12 millimeter diameter should be used.

– Steel Chairs minimum of 12 mm diameter bars to be used.

– Longitudinal steel reinforcement should not be less than 0.8% and more than 6% of gross C/S.

– The minimum bars used for a square rcc column are 4 No’s and 6 No’s for the circular column.

– Main bars used in the rcc slabs shall not be less than 8 mm (HYSD) or 10 mm (Plain bars) and the distributors not less than 8 mm and not more than 1/8 of slab thickness.

– The minimum thickness of the rcc slab should be 125 mm.

– The free-fall of concrete is allowed a maximum of 1.50m in height.

– Lap splices shall not be used for bars larger than 36mm.

– Water absorption of bricks is limited to not more than 15%.

– PH value of the water used should not be less than 6 (six).

– The minimum Compressive strength of Bricks is 3.5 N/mm2.

– The binding wire required in steel reinforcement is 8 kg per Metric tone.

– For soil filling work as per IS code, 3 samples should be taken for the core cutting test for every 100 m2.

Thumb Rules in Civil Engineering

Thumb rule requirement of standard materials and standard calculation in high raised building,

Steel =3 to 5 kg / sqft.

Cement =0.5bags/ sqft.

RMC =0.05 m3/sqft.

Block =12.5 nos /sqm.

Electrical cast = Rs 133/sqft.

Plumbing cost = Rs 126/sqft.

Fire fighting cost = Rs 40/sqft.

External development = Rs 94.5/sqft.

Very informative.

Thank you so much for sharing this

Thanks for comment, For more related posts please visit Civil, Arch, Electrical and Mechanical Tab in File menu

Thanks for comment, For more related posts please visit Civil, Arch, Electrical and Mechanical Tab in File menu

Is volume of concrete required = 0.038 m3 /square feet area or square meter area ? Kindly confirm

Thanks for comment, For more related posts please visit Civil, Arch, Electrical and Mechanical Tab in File menu

Dear Quantity Approved Control teen

..*Thank you for sharing*😊

It’s square feet area

Thanks

Excellent this subject

Thanks so much for these insights. It has helped me so much.

Do you have any thumb rules for wall slab structures? If so, can you please give it

I will post soon

very Fast and quick assessment for any type of building project generally for EPC Contract it is very useful. Thanks

Thanks for comments please get in touch for more knowledge