Table of Contents

Method Statement for Bituminous Damp Proofing for Concrete and Masonry | Work Procedure

In this Article today we will talk about the Bituminous Damp Proofing | Waterproofing Method Statement pdf | Bituminous membrane waterproofing method | Bituminous Membrane Waterproofing | Damp Proofing for Concrete | Damp Proofing for Masonry Works | Method Statement for Waterproofing Works | Method Statement for Bituminous Waterproofing

Method Statement for Bituminous Damp Proofing for Concrete and Masonry:

1. Objective:

The objective of this Method statement is to describe about materials, surface preparation, application procedure, safety measures and tools & equipment etc. for bituminous, damp proofing for concrete protection and masonry with the requirements of the specifications, standards and constructions procedures.

2. Purpose and Scope:

The purpose of this method statement is to describe the procedure for concrete protection and for masonry in compliance with the contract documents and approvals for the project.

3. Reference and Standards:

- Project Specifications

- Project Drawings Issued for Construction (IFC) Waterproofing Method Statement pdf

4. Responsibilities:

4.1 Project Manager:

It is the overall responsibility of PM to organize resources to perform construction activities as per project specifications in compliance with quality, schedule and safety requirements.

4.2 Construction Manager:

It is the responsibility of CM that construction activities are being executed according to the relevant project specifications, in compliance with quality, schedule and safety requirements. Waterproofing Method Statement pdf

4.3 Civil Engineer:

Civil Engineer shall monitor all the construction activities plastering Work in accordance with project specifications, IFC drawings by following the safe conditions under the contractor’s site safety plan. Damp Proofing for Masonry Works

4.4 QA QC Inspector:

- QA/QC Inspector shall make sure the following items and carry out all field inspections under project specification 01400 related to the quality control services.

- He will ensure the material shall conform to project specification and approved samples.

- Work should be carried out as per latest revision of drawings.

- He will confirm the storage and placing of the materials on site and other arrangements as per IFC drawings.

- He will monitor the quality of works and in conformance with the IFC drawing as per approved checklist. Damp Proofing for Masonry Works

- He will keep records of all inspections and testing related to the activity.

- He will implement the ITP with associate checklist as per sequence of work activities.

4.5 Safety Inspector:

- Supervise on-site health & safety control and promote the safe conduct of site work and environmental protection;

- Responsible for overseeing and ensuring the keeping of up to date SHE records, forms and files in accordance to the Project H&S Plan to ensure compliance and to enable auditing to be carried out;

- Ensure application of, and the adherence to, the BAYTUR Integrated H&S Management System;

- To prevent unsafe acts being undertaken by anyone on the site and to stop and prevent work to continue I commence in prevailing unsafe conditions;

- Ensure that ALL employees I workers (including subcontractors) are issued with and properly use the correct PPE and safety devices for the work being performed;

- Report any incidents, accidents or near misses immediately, as per the BAYTUR procedure, (this may include liaison with police and / or authorities) and to secure the area by preventing that the area be tampered with;

- Investigate incidents, accidents and near miss events to determine the root, basic and immediate causes and ensure that correction I corrective I preventative actions are implemented for all H&S related events.

- Ensure site welfare facilities (rest areas, water, toilets, etc.) are sufficient for the number of personnel, and are being provided by the site supervisory staff as well as ensuring that high standards of hygiene are maintained;

- Promote a positive SHE attitude to personnel, subcontractors, consultants and clients;

- Be proactive in addressing operational SHE issues to ensure that the risk to workers and others are managed, minimized and prevented as well as the potential environmental impact prevented / mitigated;

- Ensure and facilitate communication and coordination between the company and subcontractors with respect to health & safety requirements;

- Establishing a list of hazardous tasks, requiring safe work permits, implement and maintain the required permit systems;

5. Materials for Bituminous Membrane Waterproofing:

Acceptable Manufacturers for damp proofing as per approved transmittal.

- Nitoproof 10 (fosroc)

- Fosroc Solvent 102.

5.1 Accessories:

Filler, flashing as recommended by the manufacturer.

5.2 Storage:

Nitoproof 10 has shelf life of 12 months if stored in shade below 45°C normal warehouse conditions.

5.3 Health and Safety:

- Nitoproof 10 contains bituminous material. Possible risk of irreversible effects in contact with skin.

- Wear suitable protective clothing, gloves and eye/face protection.

- Barrier creams provide additional skin protection.

- Should accidental skin contact occur, remove immediately with plenty of clean water and seek medical advice.

- If swallowed, seek medical attention immediately – do not induce vomiting.

6. Procedure and Methodology:

6.1 Preparation:

- Surface to coated must be sound, clean and free of oil or grease.

- Any oil or grease contaminated should be removed with a proprietary chemical degreaser.

- If the surface dusty, it should be primed with a coat of nitoproof 10, diluted with an equal quantity of cool, clean water and allowed to dry.

- Clean and prepare surfaces to receive waterproofing in accordance with manufacturer’s instructions.

6.2 Project Condition:

- Environmental requirements: Maintain conditions recommended by manufacturer.

6.3 Standard Compliance:

- Nitoproof 10 complies with concrete curing requirements of ASTM C 309-93 when applied at a rate of 2 m.sq per litre and to BS 6949:1991 requirements for bituminous coating.

6.4 Application:

- Install materials in accordance with manufacturer’s instructions and prime surfaces in accordance with manufacturer’s instructions

- Apply to walls in internal wet areas up to height of tiling or stone cladding.

- Apply below external double skin masonry walls.

- Apply to concrete and block work below grade.

- Apply to external concrete and block work backings to external cladding.

- Apply to under sides of sloping concrete canopies to receive finishes.

- Apply where shown on drawings.

- Fill depressions, holes and cracks with a material compatible with the damp proofing.

- Expansion and control joints in below grade walls.

- Install joints before application of damp proofing.

- Primer substrate which is to receive flashing adhesive as recommended by adhesive manufacturer.

- Ensure that center portion of neoprene flashing over joints (25mm from each side of joint center line) is not bonded. Do not stretch flashing over joint.

- Trowel flashing adhesive continuously along each edge of neoprene flashing.

- Concrete surface shall be waterproofed with Nitoproof 10, a bitumen emulsion protective coating. It shall be applied at a rate of 2 msq per litre, and thus act as a combined

waterproofing and curing agent in accordance with ASTM C309.

6.5 Quality Assurance:

- Perform work in accordance with manufacturer’s instructions.

- Test material samples in accordance with ASTM D449, D450.

- Maintain one copy of each document on site.

7. Resources Requirement:

7.1 Man Power:

- Site engineer

- Supervisor

- Foreman

- Skilled Man Power

7.2 Tool and Equipment:

Tools & equipment shall comprise, but not limited to:

- Light weight foam concrete machine.

- Mason tools, trowel, and rubber gloves, face shield, safety belts gum boots.

8. Protection of Finished Work:

- Where applicable protect finished work under provisions of section 01500.

- Do not permit traffic over unprotected or uncovered bitumen.

- All finished work shall be protected under contract requirements.

OTHER POSTS:

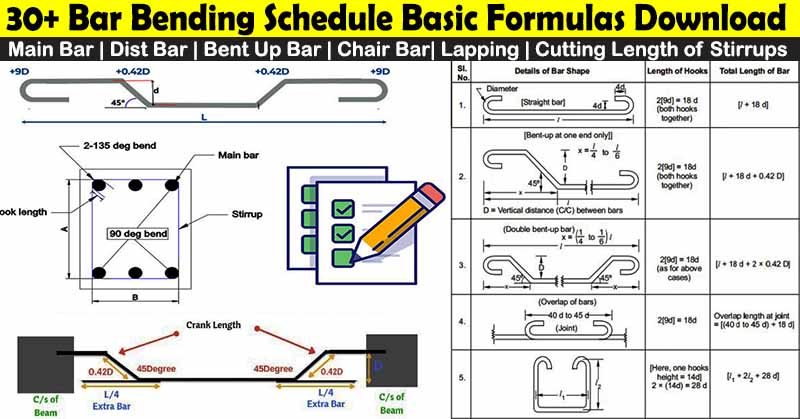

- How to Prepare Bar Bending Schedule

-

Method Statement of Polyurethane Waterproofing for Walls and Roof

- Thumb Rules for Civil Engineering

-

Can You Lay Asphalt In Winter

-

Method Statement for Trench Excavation and Backfill for Electrical Cables

Conclusion:

Full article on Bituminous Damp Proofing | Waterproofing Method Statement pdf | Bituminous membrane waterproofing method | Bituminous Membrane Waterproofing | Damp Proofing for Concrete | Damp Proofing for Masonry Works | Method Statement for Waterproofing Works | Method Statement for Bituminous Waterproofing. Thank you for the full reading of this article in “QA QC in Construction” platform in English. If you find this post helpful, then help others by sharing it on social media. Please share this article on social media for future uses.