Last updated on: August 29, 2025

Do you know that over 70% of high-rise buildings in big cities use crank bars in slabs? These are key parts of their reinforced concrete structures. They help keep RCC slabs, beams, and columns stable and strong, supporting our tall buildings.

Crank bars, also known as bent-up bars, are special steel bars used in concrete structures. They are placed carefully to strengthen concrete elements, making them crucial for any well-built building.

Before reading this article, you must know about the following:

Key Takeaways

- Crank bars are used in slabs, beams, and columns to provide additional strength and resistance against bending stresses.

- They are designed to address the negative bending moments and compressive stresses that can occur in these structural members, particularly at the points of support.

- Crank bars in slabs have to be positioned and inclined in a particular way; usually, they are at 45° or 30° slabs, and this is important in determining the total capacity of the building.

- Crank bars are crucial when it comes to issues of cracking, sags, and other undesirable structural failures that may persist in the construction process, making them an important part and parcel of today’s construction.

- Knowledge of the role and characteristics of Crank bars in slabs is highly relevant for civil engineers and construction specialists for achieving the best performance and safety of the structures.

In this article, we’ll look at why crank bars are important in slabs, beams, and columns. We’ll talk about their purpose, how they’re placed, and their benefits in concrete construction. Let’s discover how these unsung heroes shape our city skylines.

What Are Crank Bars?

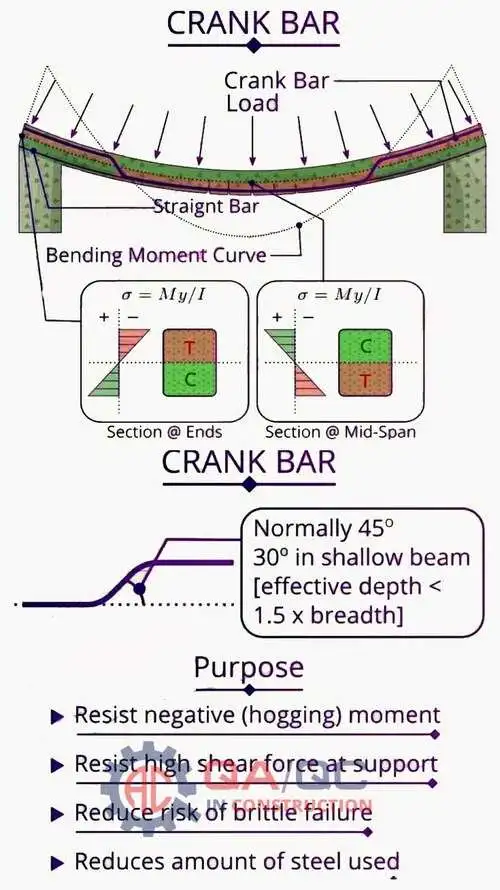

Crank bars, also known as bent-up bars, are reinforced steel bars employed in concrete structures ranging from slabs, beams, and columns. Near the supports, they are bent at specific angles of 45° or 30°. Here’s a detailed look at their definition and purpose:

Definition of Crank Bar (Bent Up Bar):

A crank-bar is a steel bar that has to be bent to certain angles to increase the strength of a concrete component. Indeed, the bends increase the possibility of anchoring well into the concrete, thus providing effective resistance to tensile and compressive forces. The main function of these bars is to balance bending moments that appear in the structure’s members under loads.

Why Crank Bars are Provided in Slab:

When the dead load of the slab and uniform live load over it act in the downward direction, the forces in the end support or continuous support act in the upward direction to counterbalance the slab load.

This action creates two types of bending moments in the structure. They are hogging and sagging-bending moments.

The bottom reinforcement part of the crank bar resists the sagging bending moment, and the upper bent-up part of the crank bar tackles the hogging bending moment (negative moment).

Bent-up bars are provided near the end supports on the top of the slab. It can be provided in the middle (mid-span) if there is any mid-support provided.

Purpose of Crank Bars in Slab:

| Crank Bar Characteristics | Purpose |

|---|---|

| Resist Negative Bending Moments (Hogging) | Cranks or bent-up bars are used to fight negative bending moments at supports. These moments can cause failure if not handled right. |

| Managing Shear Forces | Shear forces are highest at slab supports. Crank bars spread these forces, boosting the structure’s stability. |

| Reducing the Risk of Brittle Failure | Cranks add extra strength at key points, lowering the chance of sudden failure. This is especially true at slab-column connections where stress builds up. |

| Material Efficiency | Using crank bars can also cut down on steel needed, saving money on construction. |

| Structural Integrity | They make the slab stronger and more flexible, keeping the structure stable. |

Crank Bars in Beams:

Crankbars or bent-up bars are key in making slabs and beams strong. They are used in RC beams for a few main reasons.

Purpose of Crank Bars in Beam:

| Crank Bar Characteristics | Purpose |

| Shear Resistance | The main job of crank bars is to boost shear resistance. Beams face high shear stresses, especially near supports. The bars bent up fight these diagonal forces well. |

| Moment Transfer | They also help move bending moments from the tension area to the compression zone of the beam. This makes the beam stronger against bending. |

| Crack Control | Crank or Bent bars also stop diagonal shear cracks from spreading. These cracks are common in beam-critical areas. |

| Reduced Congestion | Using crank bars can mean fewer vertical stirrups are needed. This reduces steel congestion in the beam. |

| Material Efficiency | Crank bars make it easier to use reinforcing steel. They add strength where it’s needed without adding too much weight. |

| Anchorage Enhancement | The bent shape of these bars helps with anchorage in the concrete. This improves the bond between steel and concrete. |

| Reduced Beam Depth | In some cases, crank bars can help make the beam shallower. This while keeping the strength the same. |

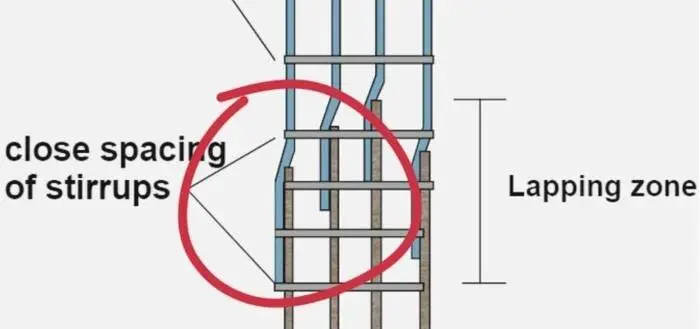

Crank Bars in Column:

Bent-up bars in columns boost the structure’s strength and stability. Here’s why:

- Resist Shear Forces: Crank bars fight high shear forces, especially when vertical ties are too close.

- Increase Bond Strength: They make the bond between steel and concrete stronger. This boosts the structure’s stability.

- Distribute Load Evenly: The bends in the bars spread the load evenly. This reduces stress points.

- Prevent Brittle Failure: They lower the chance of brittle failure at the slab-column connection.

Crank Bars Specifications:

Following are some bent-up bar specifications:

- Crank: Only alternate bent-up bars will be cranked in case of a one-way slab and both sides of bent-up bars are provided in case of a two-way slab.

- Angle of Bending: Crank bars are generally bent at angles between 30° and 45° (in deep beams), depending on the effective depth of the beam or slab. For shallow beams (effective depth < 1.5 times the breadth), a 30° angle may be used.

- Length Calculation: The crank length can be calculated using the formula: Crank Length = L/4 or L/3 (near internal supports in case of continuous beam), where L is the span length of the beam or slab. This positioning is crucial for effective load distribution.

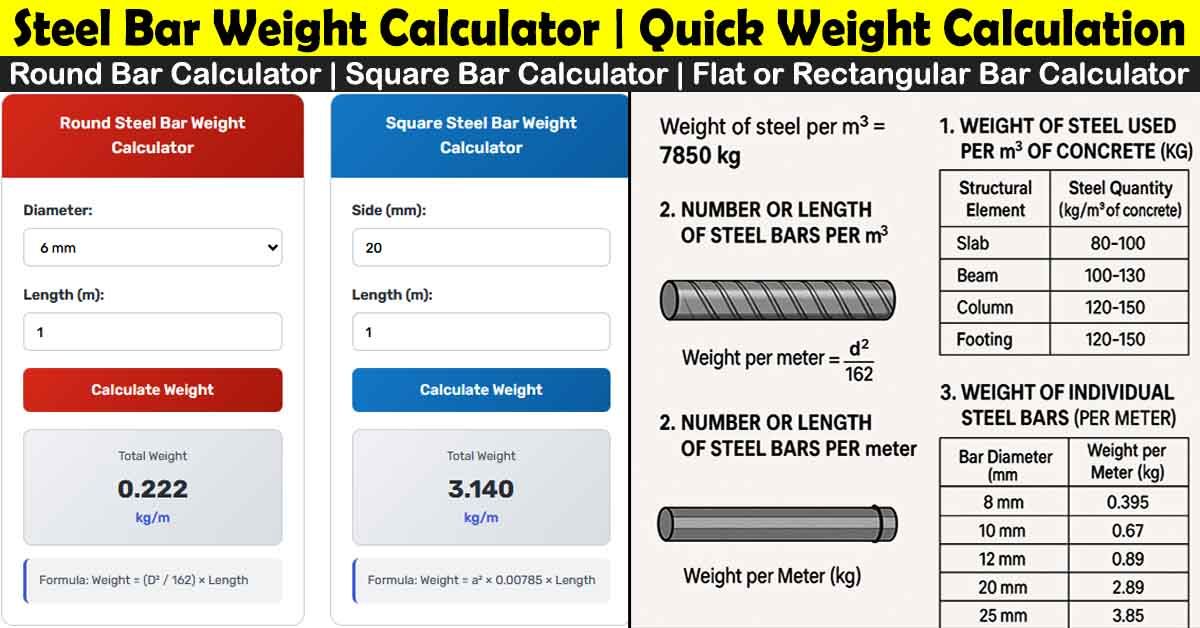

- Development Length: The development length (Ld) for crank bars must be sufficient to ensure proper anchorage within the concrete. It can be calculated based on factors including bar diameter and concrete strength.

- Slope: Crank bars or bent are provided in the slab at the slope of 1:10.

- Crank Length: Crank bars in the R.C.C. slabs or beams will be provided for at least 300 mm in length.

- Spacing Requirements: The spacing between crank bars should not exceed 300 mm for beams, ensuring adequate reinforcement density to handle tensile stresses effectively. Bent bars should be installed at the recommended spacing, typically 6 inches center to center or 4-inch center to center spacing is often recommended for crank bars in structural engineering based on design specifications.

Crank Bar Formula:

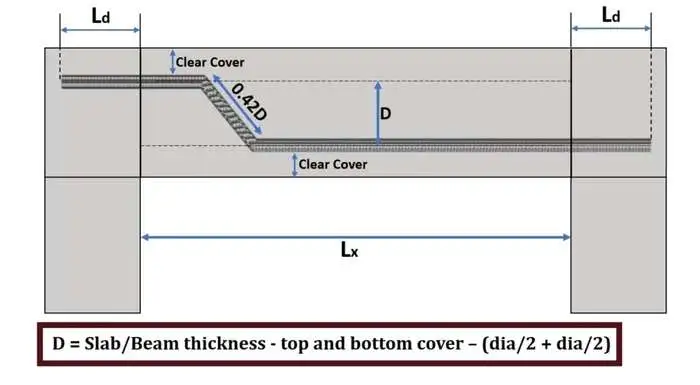

The crank length formula helps figure out the bent part of a reinforcement bar in concrete structures. This crank part fights against shear forces and bending moments at key spots like supports.

The length of the bent part depends on the angle of the bend (usually 45°) and the depth of the slab or beam (called D). D is the clear depth minus the top and bottom cover.

Crank Length Formula:

Crank Length = D × (sinθ − tanθ)

Where:

- D = Depth of the slab or clear height of the bar (depth minus top cover and bottom cover).

- θ = The angle of the crank (typically 45° or 30°).

For a 45-degree crank (which is the most common):

Crank Length = D × (sin 45∘−tan 45∘)

Crank Length = 1.42D – D = 0.42D

Explanation:

- 1.42D comes from the trigonometric values for the 45° angle.

- D is subtracted to account for the clear bar height.

- The result, 0.42D, gives the length of the crank, which is typically about 42% of the clear depth of the slab or beam.

For a 30-degree crank:

The formula changes a bit because sine and tangent values are different.

This bent or crank length is key to ensuring proper reinforcement in high-stress areas. It helps prevent shear failure and spreads out the load better.

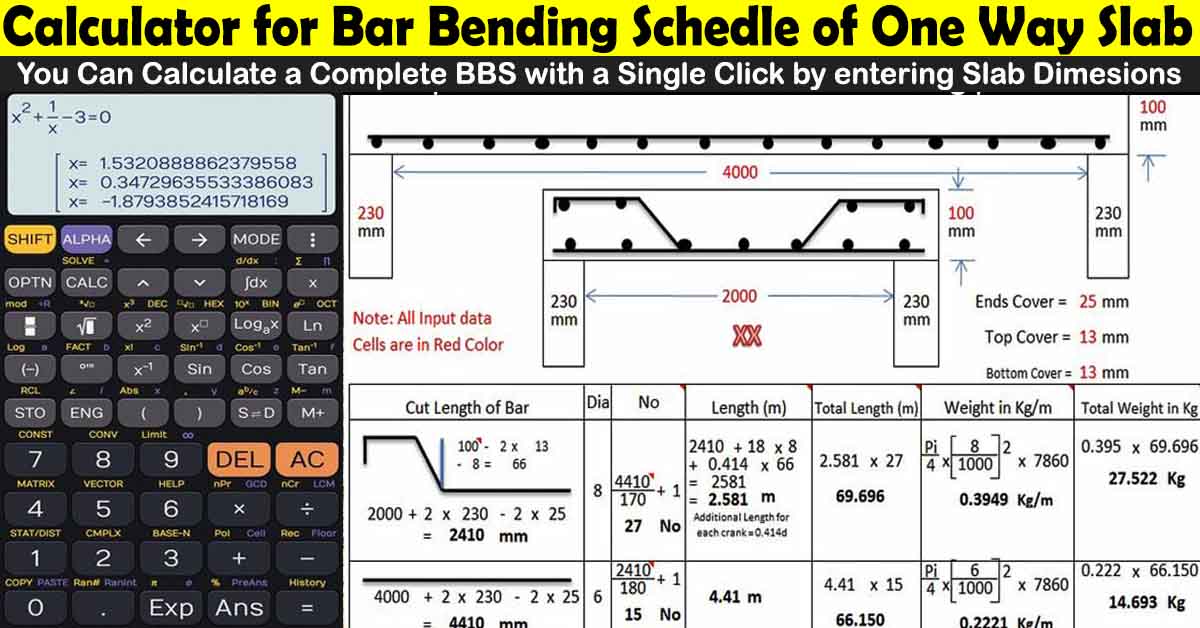

How to Calculate Crank Bar Length in Slab or Beam?

To find the length of a crank bar, use the slab or beam’s dimensions and bending angles. Here’s how to figure out the cutting length of a crank bar:

Step-by-step Calculation (Example):

Given Data:

Clear span of the slab (L): 2000 mm

Development length (DL): 40 mm (for anchorage)

Inclined length (IL): 0.42 * effective depth (D)

Effective depth (D): Thickness of slab (top cover + bottom cover + bar diameter)

Assume thickness = 150 mm, top cover = 25 mm, bottom cover = 25 mm, bar diameter = 16 mm.

Step 1: Calculate Effective Depth

D = 150 − ( 25 + 25 + 16 ) = 84 mm

Step 2: Calculate Inclined Length

IL = 0.42 × D = 0.42 × 84 = 35.28 mm

Step 3. Calculate the Cutting Length of One Crank Bar

Using the formula:

Cutting Length = L+ ( 2 × DL ) + IL − ( 2 × bar diameter )

Plugging in the values: Cutting Length = 2000 + ( 2 × 40 ) + 35.28 − ( 2 × 16 )

Simplifying: Cutting Length = 2000 + 80 + 35.28 − 32 = 2083.28 mm

Step 4. Total Length for Multiple Crank Bars

If you need, for example, 35 crank bars: Total Length = Cutting Length × Number of Cranks Bars

Therefore: Total Length = 2083.28 × 35 = 72914.8 mm = 72.9148 meters

Result

The cutting length of one crank bar is approximately 2083.28 mm, and for 35 crank bars, the total length required is about 72.91 meters.

Conclusion:

In conclusion, crank bars are crucial for the strength of concrete elements like slabs, beams, and columns. They help resist bending moments, shear forces, and brittle failure, especially at supports and slab-column connections. By spreading out stresses, crank bars add strength, stability, and durability to buildings. They are vital for the safety and performance of high-rise buildings and other concrete structures.

FAQ:

What is the Purpose of Providing Crank Bars in Slabs and Beams?

Crank bars, also known as bent-up bars, help resist bending and shear forces near supports. They improve the bond between steel and concrete, adding strength and stability.

How do crank bars improve the structural integrity of slabs and beams?

Crank bars spread loads evenly, lowering stress and failure risks. Bent at 45° or 30°, they work well in tension and compression zones.

Why are crank bars bent at specific angles?

The angles, usually at an angle of 45° or 30°, meet structural needs. These angles help resist negative moments and shear forces effectively.

Can Bent-up bars reduce the amount of reinforcement needed in construction?

Yes, crank bars can cut down on needed reinforcement. This saves on steel costs while keeping structures strong.

What are the benefits of using crank bars in reinforced concrete structures?

Crank bars boost bond strength, distribute loads better, and lower failure risks. They also handle dynamic loads and vibrations well.

This kind of study matters is more beneficial to many people such as professionals, engineers, teachers, instructors, Technologists and students. Thanks so much for work done. However, I wish to have soft copy of this work.

Thanks for comments please get in touch for more knowledge