Last updated on: April 24, 2022

Method Statement for Installation of Drainage Piping System

In this article today we will talk about the Installation of Drainage Piping System | Drainage System in Plumbing | Drainage Pipe Installation Guide | How to Install Drainage Pipe | Drainage in Plumbing | Drainage Construction Procedure | House Water Drainage System | Safe Work Method Statement for Plumbing| Installing a Drainage System in your Yard

Method Statement for Installation of Drainage Piping System:

1. Purpose:

This method statement defines the task and introduces correct practices in order to ensure that the job execution will meet the requirements in a safe system at work.

2. Scope of Work:

- The method statement outlines the methodology for the installation and testing for drainage piping System. “Contractor Name” is Responsible for installation, testing and final hand over of CP 04 (a & b) Drainage System in Plumbing

- DEFINITION & REFRENCE DOCUMENTS:

Programme Minimum H&S Construction Standard Drainage Pipe Installation Guide

3. References:

- Drainage Shop Drawings

- Technical Specification

- Project Quality Plan

- Material Submittal Approval & Installation Guide Line.

- Programme Minimum H&S Construction Standard Drainage System in Plumbing

4. Material & Tools:

- Cast iron pipes & fittings

- Unlpasticized polyvinyl chloride (upcv)

- Repair Paint for pipes

- Support & Hangers

- Drilling machine Drainage Construction Procedure

- Pipe Cutter (Disc cutter / Hacksaw)

- Screw driver

- Tool Box

- Measuring tape

- Sprit Level Drainage Pipe Installation Guide

5. Work Procedure – General:

5.1 Transportation and Handling:

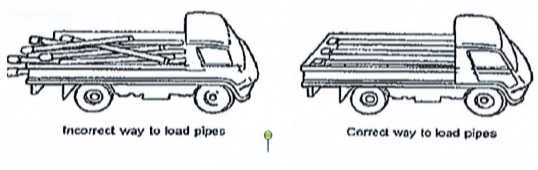

Pipes and fittings shall be transported to the site by the contractor, in the appropriate vehicle such that no damage is done during transportation. The pipes should be evenly supported throughout their length. Pipes should be handled with care, make sure they are not dropped on hard surfaces, rolled on the ground or dragged. Where possible, pipes should be unloaded by hand. If mechanical lifting equipment is to be used, web slings are preferred as they do no gouge or scratch the surface of the pipe. Drainage Pipe Installation Guide

5.2 Storage and Inspection:

The storage area must be flat, the ground must not be marshy or unstable and it must not

contain any corrosive material. While loose pipe shall be stacked on a clean, flat surface, free of sharp projections and other sources of point loading. The pipes must be stocked in the respective stakes according to diameter in accordance with a logical plan. The same is

applied for fittings and accessories. Pipes & fittings should not be exposed to prolonged solar radiation and covered from direct sunlight. Store all fittings in their original packaging until required for use, in well ventilated, shady conditions and do not expose to direct sunlight. Couplings should be stored in cool area protected from light, direct sun light and strong artificial light with a high ultraviolet content. How to Install Drainage Pipe

The pipes should be stacked as per recommended manufacture instruction to avoid over

stress and possible damage. All the used material should be as per approved material submittals and approved area of application as indicated in the project documents.

5.3 Material Inspection:

Upon receipt of materials on site, the Storekeeper and Site Engineer or representative will

have to check to ensure that the materials delivered and their respective quantities are correct. A Material Inspection Request shall be issued and all materials must be inspected

and verified by the Engineer. When approved, the materials will be considered correct with

respect to their approved sample(s), catalogues and technical reports. How to Install Drainage Pipe

6. Installation Procedure:

6.1 Site Preparation:

Access and ingress shall be ensured by clearing the area from unnecessary and not relevant to the task materials. Access and ingress shall be ensured by stacking materials relevant to the task according to the work schedule. How to Install Drainage Pipe

6.2 Pre-installation:

Pipe layout shall be as per the approved shop drawings. The installation shall be planned in

advance to match with the main contractor’s program of works. All materials and tools to be kept ready on site prior installation works. All material will be visually inspected for damage before installation and verified that it is undamaged. Project specification, standard codes, and work procedures shall be followed. Approved supports shall be used to support the pipes & fittings. Site fabrication shall be allowed for necessary requirement of supports as per applicable standard if required. How to Install Drainage Pipe

6.3 Installation of Pipes:

- The position of all pipes and supports shall be marked where possible.

- Piping is to be installed as per the approved shop drawings.

- Any deviations to the layout shall be subject to approval of coordination drawings.

- Piping shall be installed at appropriate slopes, free of sags and sharp bends, as per the

approved shop drawings. Drainage in Plumbing - Throughout the installation the open ends of pipes shall be protected from entry of debris Drainage Construction Procedure

- Used the required fittings such as ring seals which are necessary and mandatory to accommodate the expansion and contraction action as per project Specification and

drawings. Drainage in Plumbing - Rubber Socket with clamps, Flanges, Dielectric Union etc. joint to be used as required to connect the cast iron and upvc pipes as per project Specification and drawings.

6.4 Detailed Permanent Works Installation Instructions:

6.4.1 Pipe Cutting:

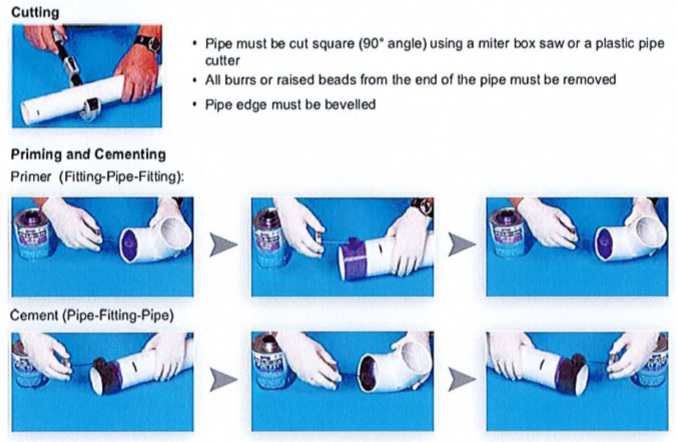

Pipes shall be cut on site using disc-type cutter or by other cutting tools. The pipe must be cut square (90 angel). This can be done easily by wrapping a metal sheet around the pipe with no overlap on the edges, marking around the pipe and cutting along the marked line.

6.5 Installation of coupling Cast Iron Pipe & Fittings:

6.5.1 Assembly as a Sleeve:

- Push the supplied assembled coupling onto the pipe spigot so that it abuts on the

central register of the elastomeric gasket. (See Fig, 1) - Push the next pipe spigot into the other end of the coupling. (See Fig. 2).

- Tighten the screw to “null gap” position with screwdriver. (See Fig. 3).

The PAM Rapid NG is designed to be tightened to fully closed; there is no need for checking the torque. Drainage Pipe Installation Guide

6.5.2 Assembly as Separate Assembly:

- Push the supplied sealing gasket on to the pipe spigot so it abuts the gasket central

register (see Fig.1). Drainage System in Plumbing - Roll back the open half of the sealing gasket (see Fig.2).

- Install the next spigot and unfold the gasket half back (see Fig.3)

- Place the steel strap around the sealing gasket (see Fig.4).

- For couplings with two screws, alternately tighten the two tightening screws uniformly and hand tight. The threaded plates must come together parallel to avoid any deformation. For single screw couplings, tighten the single hexagon head screw (see

Fig-5) How to Install Drainage Pipe

6.5.3 Installation of Grip Collars:

- Position the two half parts of the PAM grip collar uniformly so it encircles the pipe in parallel. The grip collars must be positioned so that the apertures fit over the fixing bolts of the coupling and the teeth are directly located onto the pipe.

- Insert the four screws to fix the two parts together loosely. The positioning must be cautiously made, so that the grip collar windows are not seated on the clamps of the coupling and the claws are not swatting the coupling strap.

- Tighten the screws crosswise alternatively so that the two plates are put in parallel with

the same spacing. Installing a Drainage System in your Yard - The assembly is completed when the external edges of the plates are in contact on both

sides. Installing a Drainage System in your Yard

- Grip collars shall be installed around the coupling to secure the couplings unspecific cases like changes of direction, gradient or some components like branches and plugs, where the junctions exposed to the excessive pressure undergo end thrust forces that have to be addressed. Installing a Drainage System in your Yard

6.6 Installation of UPCV Pipe & Fittings:

- 110mm dia.to 315mm dia shall be installed in upcv pipe work and fittings to SAS14

Class3 Installing a Drainage System in your Yard - 90mm dia Pipe work and below shall be installed upcv and fittings to 8AS14 Class 4

- Jointing of pipe work and fittings shall be by the use of solvent weld sockets carried out in accordance with manufacture instructions. Solvent weld cement shall be of a type approved by the manufacture of pipe work being jointed.

- After getting the all civil clearances (including Raft Slabs , levels, blinding, water proofing & steel fixing), prepare the pipe length & all accessories as per the approved shop drawing for the laying where applicable. Safe Work Method Statement for Plumbing

- Proceed with pipe Installation with the appropriate Slope and Route as per the approved

Shop Drawing using suspended supporting system as per the project specification & leakage test to be applied to insure no leakage from joints & pipes - Measure length of pipe required, making due allowance for any pipe fittings to be used. Cut the pipe to the measured length. Ensure that the ends are cut square and clean all burs. A chamfer to the depth of half wall thickness to be applied to each spigot.

- The spigot and socket to be jointed should be carefully examined for any damage which could impair the jointing procedure.

- The spigot insertion depth should be measured as the depth from the mouth to the shoulder of the socket. Safe Work Method Statement for Plumbing

- The insertion depth should be marked on the spigot using marker.

- The jointing system for drainage piping system is ”Solvent weld”

- The mating areas of the spigot and the socket should be thoroughly cleaned using the pipe cleaner and a clean rag. Safe Work Method Statement for Plumbing

- Using brush apply an even layer solvent cement to the spigot and socket mating surfaces. House Water Drainage System

- The cement should be applied in a lengthwise direction and not with a circular motion.

- The cement should be applied simultaneously to the spigot and socket by two people.

6.6.1 Solvent Cement Welding:

This method of joining is very simple and reliable if it is followed correctly, but any deviations from the recommended basic steps may reduce the strength and integrity of the joint. The procedures for preparation, insertion, and curing should be followed. For further details please consult National Marketing sales office. House Water Drainage System

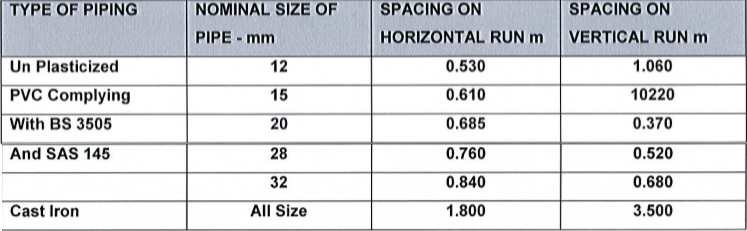

6.7 Supports Installation:

Pipes shall be supported adequately using approved hangers & supports, at maximum support spacing of 1.8 m for horizontal pipes & 3.5 m for vertical pipes for all pipe sizes as per project Speciation. House Water Drainage System

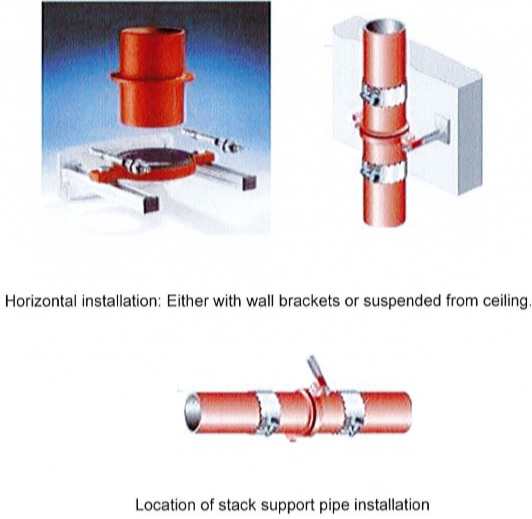

6.7.1 Installation of Stack Support Pipes:

Vertical installation: Either on cantilever arms or stack support consoles

- Shall be installed at the base of every Soil, Waste & Vent Stack

- Shall be installed where end thrust forces occur as shown in previous detail.

6.7.2 Pipe Hanger Installation:

Location of the hanger to be marked as per approved shop drawings, and Specification:

- Install drop-in anchor House Water Drainage System

- Install the pipe either by screw fitting or coupling.

- Select the hanger based on the pipe size. Install the hanger rod to the drop in anchor.

- Install the hanger to pipe and hanger rod. Drainage Construction Procedure

- Tighten the bolt and nut holding the hanger rod and hanger evenly.

6.8 Installation of Sleeves:

Where the pipes crossing the fire rated walls, floors or roofs approved fire stopping material shall be used to fill the annular space between the pipe surface and sleeve. The method of application shall be as recommended by the approved fire stopping material manufacturer. The fire sleeve shall have a fire rating compatible to the fire rating of wall, floor or roof being crossed. Drainage Construction Procedure

6.9 Post Installation:

On completion of the works, relevant section shall be visually inspected to ensure that the

correct installation procedures have been followed, and that the pipes and fittings are adequately restrained and supported, as per the Project Specifications. Drainage Construction Procedure

7. Codes and Standards:

The operation shall be carried out in accordance with the approved shop drawings, specifications, approved material submittals and specified international standards.

OTHER POSTS:

-

Inspection and Testing Procedure of Drainage Piping after Installation

-

Method Statement for Installation of Water Pumps

-

Method Statement for Welding Works | Welding Techniques

Conclusion:

Full article on Installation of Drainage Piping System | Drainage System in Plumbing | Drainage Pipe Installation Guide | How to Install Drainage Pipe | Drainage in Plumbing | Drainage Construction Procedure | House Water Drainage System | Safe Work Method Statement for Plumbing| Installing a Drainage System in your Yard. Thank you for the full reading of this article in “QA QC in Construction” platform in English. If you find this post helpful, then help others by sharing it on social media. Please share this article on social media for future uses.

Hi