Last updated on: August 29, 2025

In any construction project, building a strong, durable concrete slab is essential for the project’s success. Using the appropriate reinforcement is crucial to ensure the slab can bear the intended loads. A steel weight calculator for one way slabs is a helpful tool, specifically designed to determine the amount of steel required.

This article will cover why reinforcement is important, what one-way slabs are, and how to use the one way slab reinforcement calculator. We’ll also talk about the benefits of using it, and the importance of rebar spacing. By the end, you’ll know how to plan and do your concrete slab reinforcement projects well.

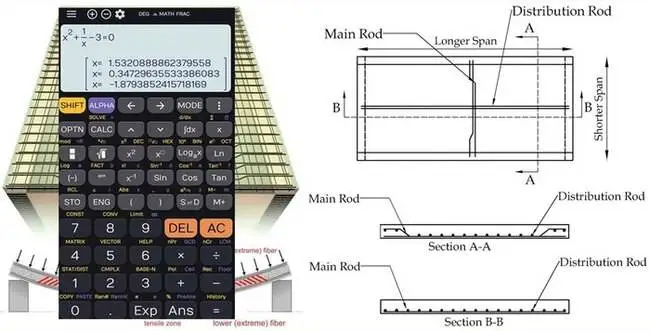

Before reading this article you must know about the following:

What is a One-Way Slab:

A one-way slab is a type of concrete slab designed to transfer load in just one direction usually across a beam or along a wall. Because it doesn’t support load in both directions, it works well for certain types of structural projects compared to two-way slabs.

Importance of Steel Weight Calculation

The weight of steel rebar in one-way slabs is calculated for three important reasons:

- Cost Estimation: Through accurate calculations, it is possible to record budgets and order the materials required.

- Load Bearing Consideration: It is important to ensure that the anticipated loads can be safely supported by the slab as designed without collapse.

- Material Efficiency: This ensures that there is no unnecessary wastage by establishing the appropriate amount of steel to be used.

Steel Weight Calculator for One Way Slab Online

Note: You can change the input parameters as per your Slab Dimensions

Input Data

How to Use a Steel Weight Calculator for One Way Slab

To use a Steel Quantity Calculator, you need to enter the input parameters into the calculator. This includes the following:

Key Inputs Required for One Way Slab Reinforcement Calculator

- Slab Dimensions:

- Length (L)

- Width (W)

- Thickness (h)

- Reinforcement Details:

- Diameter of main bars

- Diameter of distribution bars

- Diameter of Extra bars

- Spacing between bars

- Clear Cover:

- The minimum distance between the surface of the concrete (excluding any coatings or plaster) and the outermost surface of the steel reinforcement.

Step-by-Step Process for Steel Quantity Calculation with Rebar Calculation Formulas

To determine the weight of steel, Now, let’s go through each step in detail with Rebar Calculation Formulas for the calculation procedure:

Step 1: Calculation for Main Bars

- Number of Main Bars

Number of Main Bars = (Spacing of main bars / Longer span) + 1 - Cutting Length of Main Bars

Cutting Length = Shorter span + ( 2 × Development length ) + Crank length − Bend reduction

Where:- Development length = 48 × d

- Crank length: Crank length = 0.42 × ( Slab thickness − 2 × Clear cover − Bar diameter )

- Bend reduction: For two 45° bends = 2 x d

- Total Length of Main Bars

Total Length = Cutting Length × Number of bars - Weight of Main Bars

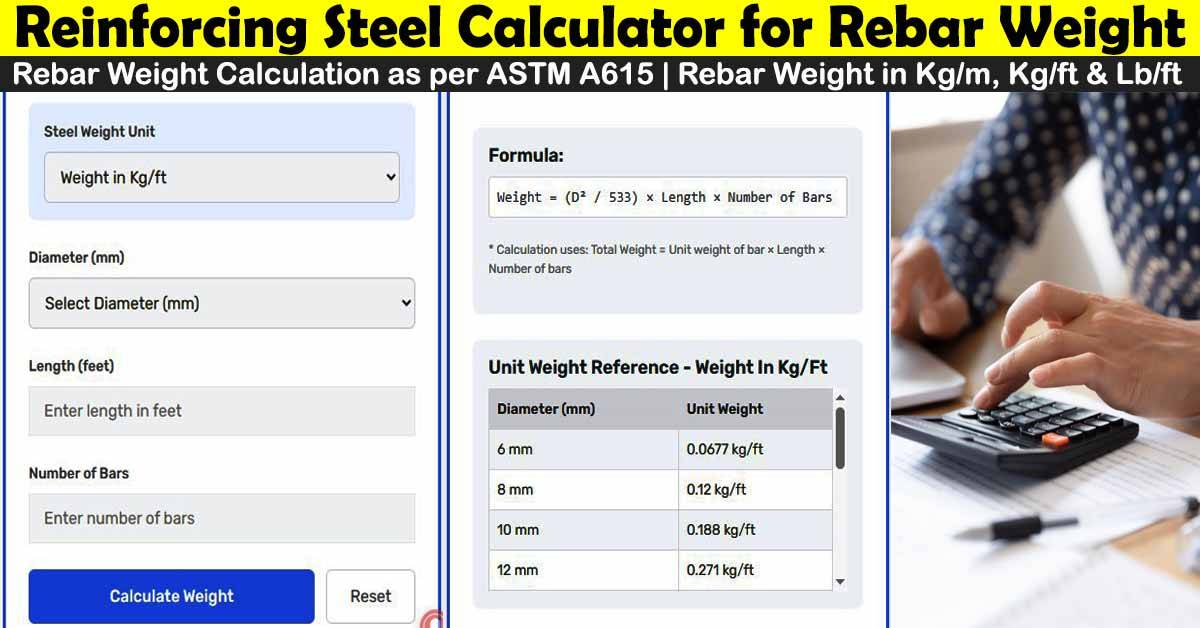

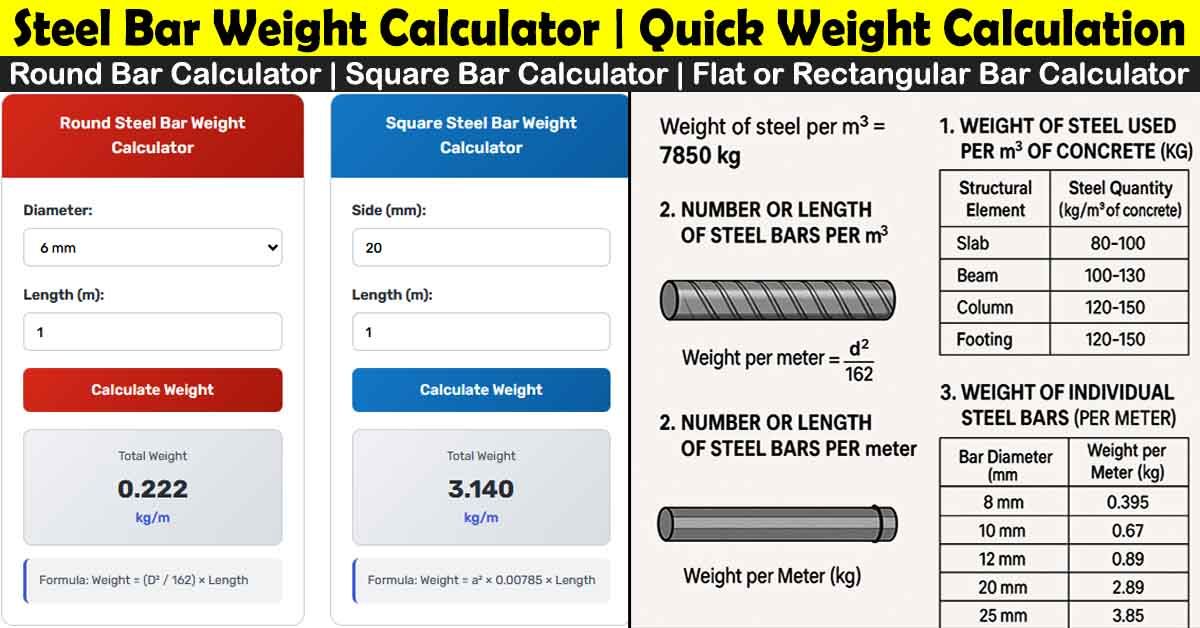

Weight in Kg’s = ( d2 / 162.2) × L

Where:- d = Diameter of bar

- L = Length of bar

Step 2: Calculation for Distribution Bars

- Number of Distribution Bars

Number of Distribution-Bars = ( Shorter span / Spacing of Distribution bars) + 1 - Cutting Length of Distribution Bars

Cutting Length = Longer span + ( 2 × Development length )

Where:- Development length = 48 × d

- Development length = 48 × d

- Total Length of Distribution-Bars

Total Length = Cutting Length × Number of bars - Weight of Distribution-Bars

Weight in Kg’s = ( d2 / 162.2) × L

Where:

- d = Diameter of bar

- L = Length of bar

Step 3: Calculation for Top Distribution Bars

- Number of Top Distribution-Bars

Number of Top Distribution Bars = [(Shorter span / 4 / Spacing ) + 1] x 2 - Cutting Length of Top Distribution-Bars

The cutting length is the same as the bottom distribution bars. - Total Length of Top Distribution-Bars

Total Length = Cutting Length × Number of bars - Weight of Top Distribution-Bars

Weight in Kg’s = ( d2 / 162.2) × L

Where:- d = Diameter of bar

- L = Length of bar

Step 4: Calculation for Top Extra Bars

- Number of Top Extra Bars

Number of Top Extra Bars = ( Longer span / Twice the spacing of main bars ) + 1 - Cutting Length of Top Extra Bars

Cutting Length = ( Shorter span / 4 ) + Development Length

Where:- Development length = 48 × d

- Development length = 48 × d

- Total Length of Top Extra Bars

Total Length = Cutting Length × Number of bars - Weight of Top Extra Bars

Weight in Kg’s = ( d2 / 162.2) × L

Where:- d = Diameter of bar

- L = Length of bar

Step 5: Total Weight of Steel

Total Weight = Weight of Main Bars + Weight of Distribution Bars + Weight of Top Distribution Bars + Weight of Top Extra Bars

Step 6: Total Weight of Steel with 5% Wastage

Total Weight with Wastage in Kg’s = Total Weight + ( 0.05 × Total Weight )

Total Weight with Wastages in Tons = (Total Weight with Wastage in Kg’s) / 1000

Example Calculation

To calculate quantity of steel for a concrete slab with the following specifications by the help of Concrete Slab Reinforcement Calculator:

- Length of Slab: 6 m

- Width of Slab: 3 m

- Diameter of Main bars: 10 mm

- Spacing of Main bars: 260 mm

- Diameter of Distribution bars: 8 mm

- Spacing of Distribution bars: 290 mm

- Clear Cover: 20 mm

- Overall Slab Thickness: 140 mm

- Convert dimensions to consistent units.

- Calculate effective depth.

- Calculate the Number of Bars

- Determine Cutting Length (Main and Distribution bars)

- Calculate the bar’s weight (in kg and tons).

- Compute Wastage

Benefits of Using a Steel Weight Calculator

Using a steel weight calculator for one way slab construction has many benefits. It makes the construction process smoother and improves project results. This tool helps construction experts work more efficiently, save money, and achieve better project outcomes.

| Benefit | Description |

|---|---|

| Accurate Steel Quantity Estimation | Precisely determines the required amount of reinforcement, eliminating material waste. |

| Reinforcement Planning | Enables efficient planning and placement of steel reinforcement. |

| Material Optimization | Identifies the optimal steel grade and size for the project requirements. |

| Construction Efficiency | Streamlines the construction process by automating complex calculations. |

| Cost Savings | Reduces material waste and enhances overall project cost-effectiveness. |

Conclusion

The steel weight calculator for one way slabs simplifies the calculation of reinforcement weight necessary in any construction project, delivering accuracy and efficiency in the process.

This tool leads engineers to informed decisions on material requirements by providing clear inputs and systematic calculations that, in turn, help to make safer and more economical structures. Online tools exist with tools like that for a specific regional standard that can help professionals a great deal in improving their planning capabilities.

FAQs

What is the purpose of the Steel Weight Calculator for One Way Slab?

The Steel Weight Calculator for One Way Slab helps construction pros figure out the steel needed for slab reinforcement. It makes planning easier.

What factors affect the steel quantity required for a one-way slab?

What factors affect the steel quantity required for a one-way slab?

Several important factors decide how much steel a one-way slab needs:

- Slab Size: Bigger slabs need more steel.

- Load Requirements: More steel is needed for heavier loads.

- Steel Grade: The quality and strength of the steel matter too.

These factors are key when using a slab reinforcement calculator.

What are the benefits of using a steel quantity calculator for one-way slab design?

What are the benefits of using a steel quantity calculator for one-way slab design?

Using a steel quantity calculator for one-way slab design saves time and boosts accuracy. It helps manage costs well. The calculator automates calculations, cuts down waste, and meets standards and codes.

How do the spacing and distribution of rebar affect the one-way slab design?

How do the spacing and distribution of rebar affect the one-way slab design?

The spacing and distribution of rebar are very important in one-way slab design. Main and distribution bars have different roles. The slab reinforcement calculator ensures a strong and compliant slab design.

How can the one-way Slab Reinforcement Calculator be integrated into construction projects?

How can the one-way Slab Reinforcement Calculator be integrated into construction projects?

The calculator aids in better project planning, managing materials, and saving costs. It improves construction efficiency overall.

How do you find the self-weight of a one-way slab?

How do you find the self-weight of a one-way slab?

To find the self-weight of a one-way slab, you’ll need to calculate the weight of the concrete per unit area. This can be done using the formula:

Self-weight = Thickness of slab (m) × Unit weight of concrete (kN/m³)

For example, if the slab is 0.15 m thick and the unit weight of concrete is 25 kN/m³, then:

Self-weight = 0.15 × 25 = 3.75 kN/m²

This self-weight calculation is essential to ensure the slab can handle its own weight as well as any additional loads placed on it.

How do you calculate the Bar Bending Schedule (BBS) of a one-way slab?

How do you calculate the Bar Bending Schedule (BBS) of a one-way slab?

The calculator above can generate the Bar Bending Schedule (BBS) for a one-way slab with complete formulas and calculations. Simply enter the required values, and it will display the full BBS as the output.

Very helpful, I honestly thank you for providing such interesting apps. My concern in addition to this, is you should also provide another calculator for two-ways slab.

Thank you once more

stay in touch i will upload soon

Hi,

Thank you for uploading such helpful information. I appreciate your effort!

Regards,

Amjad Khan

Thanks for your comments. Please get in touch for more knowledge. I will upload more construction and BBS calculators soon

It’s really very helpful. Thank you so much for this one way slab steel calculator. It really helped me alot with my concepts. As a request, could you please add a calculator for two way slab also? It will be more helpful.

Thanks for comments please get in touch for more knowledge. I will upload more construction and BBS calculators soon

Congratulations for a well elaborated,updated and summers, skill, knowledge and technique on rebar and steel blending work

Thanks for comments please get in touch for more knowledge

It’s very good tanks