Last updated on: April 24, 2022

Method Statement for Installation of Electrical Conduit and Boxes | PVC, EPVC, GI, RGS, EMT, Steel

In this article today we will talk about the Installation of Electrical Conduit and Boxes | Installation of PVC Conduits | Heavy Gauge PVC Conduits | Installation of Flexible EPVC Conduits | Installation of Steel Conduits | Installation of Embedded Conduits in Slab and Walls | Installation of Electrical Conduits | Types of Conduits | Electrical Conduit Installation Guide

Method Statement for Installation of Electrical Conduit and Boxes:

1. Purpose:

The purpose of generating this method statement is to define the procedure for Installation of Electrical Conduit and boxes through guidelines contained herein to ensure that the job execution complies with the requirement where applicable in the project. Installation of PVC Conduits

2. Scope:

This method statement covers all processes related to installation of the mentioned system as per project specification, manufacturer recommendation, approved drawings, Civil defense approval and regulation. The manpower and time scale required depends on the number of conduits and boxes which will be install. Installation of PVC Conduits

3. Reference:

- Project specifications

- Panel schedule

- Approved Shop drawings

- Single line diagram (SLD)

- Material submittal

- Project Quality plan

- Project HSE Plan

- Civil Defense Approval

- Programme Minimum H&S Construction Standard

- Health & Safety Plan

- Emergency Response Plan (ERP)

- LOTO Procedure

- Rescue Plan Heavy Gauge PVC Conduits

4. Material and Equipments:

The Following tools shall be arranged before starting the job. All Materials are as per specifications and approved material submittal.

- Mini Hacksaw Frame with Blades

- Choke Lime Powder with sufficient length of Thread

- Measuring Tape

- End Cutter

- Ladder/Scaffolding

- Manual Auger Bit

- Hammer

- Hacksaw/Jigsaw M/C

- Centre punch

- Wooden hammer

- Electrical drill (only for surface installation works)

- Diagonal- cutter pliers

- Shank screwdriver

- Drill M/C portable hand tools

- Portable drill M/C grinding M/C

- Spirit level & water level

- Step ladder Heavy Gauge PVC Conduits

Safety requirements tools such as safety shoes, safety helmet, safety glasses, fluorescent vest, and safety gloves to ensure maximum ability of safe work and dust mask when require. Heavy Gauge PVC Conduits

4.1 Material Handling and Storage:

- On receipt of the conduit, boxes and fittings materials at site necessary precautions shall be taken for unloading, shifting & storage as follows:

- Material shall be stored in a covered / dry space at all the time to avoid corrosion.

- All materials received at site shall be inspected and ensured that the materials are as

per approved material submittal. - Any discrepancies, damage etc., found will be notified and reported for further action.

- Material found not suitable for site use will be removed from site immediately.

- Storage of conduit, boxes and fittings materials should be in a clean, dry,

“NO SMOKING” area and should be restricted to access by authorized personnel only. - Storage condition shall be such that conduit, boxes and fittings materials are not subject to rough handling or physical damage. Storage shall be in cool place and in condition no humidity and moisture. Installation of Flexible EPVC Conduits

- These materials must be stored under shelter to protect the boxes from the elements and raised to protect them from dampness or wet surface.

5. Procedure:

5.1 Installation of PVC, Heavy Gauge PVC and flexible EPVC conduit (open

Conduiting) :

- Survey and mark out the exact location of all boxes in ceiling or wall conduits follow all the distances, height and marking given in the approved layout & detail drawings.

- Ensure that the work site locations have been released and ready for safe works execution especially the wall surface where boxes and conduits are to be installed.

- Rigid heavy duty PVC conduits shall be used for Lighting and power systems, Low current systems, above false ceilings and embedded areas as Per Project Specifications and approved shop Drawings. Installation of Flexible EPVC Conduits

- Expansion ring, PVC boxes, adopters, male bushes, locking nuts shall be utilized as per

approved shop drawings. Installation of Embedded Conduits in Slab and Walls - Expansion coupler shall be utilized at locations where PVC Conduits are crossing construction expansion joints.

- Connect conduits terminating in switchgear, fuse boards, trunking, adaptable boxes or other non-spouted enclosure with smooth bore male PVC bushing and sockets.

- Ensure that conduit connections are tight and fixed rigid.

- The outlets shall not run more than the permissible numbers of conduits to any surface wall outlet. Installation of Flexible EPVC Conduits

- The exposed conduit work is to be installed so as not to interfere with ceiling inserts, lights or ventilation ducts or outlets.

- Use approved hot bent method to bend the PVC conduit if conduit over 25 mm and below. Electrical Conduit Installation Guide

- 25 diameters use cold bent by bending spring.

- The conduits on walls are to be run neatly, horizontally or vertically.

- Provide pulling wire (Gl wire or equivalent strength cord) in each conduit. Secure the wire inside the box or at end of conduits and covered.

- Any changes in the routing of conduits shall be mark in the as built drawing.

- All installed conduits to be protected until the next activity and final handover.

5.2 Installation of Steel Conduit (RGS and Heavy Gauge Rigid Steel):

- Survey and mark out the exact location of all boxes in ceiling or wall (Concealed) follow all the distances, height and marking given in the approved Shop Drawing and IFC drawing. Installation of Flexible EPVC Conduits

- After verifying the exact location and provided all the necessary mark out, start installing the box by drilling in the concrete wall, column or ceiling and fixed the box.

- After completing the installation of the box, start fixing the conduits. Conduit shall be securely fastened in wall.

- Where a conduit is placed in a sheet metal enclosure or outlet boxes it shall be securely fixed using Locknuts arrangements.

- Ensure that conduit threads are properly cut. Conduit shall be cut using a saw or a roll cutter (pipe cutter). Care should be taken to ensure a straight cut. After cutting end conduit fittings are to be cleaned, cut ends are to be reamed to remove burrs and sharp edges. Installation of Steel Conduits

- Thread less couplings and connector used with conduit shall be made tight. Where installed in locations, they shall be the rain tight type. Thread less or screw type coupling and connectors shall not be used on threaded conduit ends unless listed for the purpose. Installation of Steel Conduits

- Threads of plugs, junction boxes and other fittings shall be lightly lubricated with rust

preventive grease before assembly. - Provide pulling wire (Gl wire or equivalent strength cord) in each conduit. Secure the wire inside the box or at end of conduits and covered.

- Remaining threads on galvanized steel conduits are to be filled with touch up paint.

- Any changes in the routing of conduits shall be mark in the as built drawing.

5.3 Installation of Exposed Conduits (EMT, RGS Heavy Gauge & PVC Coated):

- Survey and mark out the exact location of all boxes in ceiling or wall (exposed conduits

installation). Follow all the distances, height and marking as per approved shop drawing and IFC’s. Installation of Steel Conduits - Exposed RGS conduits shall be installed in mechanical rooms and outdoor installation.

- EMT conduits shall be used above false ceiling.

- Expansion arrangement shall be made for RGS & EMT conduits when crossing expansion

joints. Installation of Steel Conduits - Ensure that work site locations have been released and ready for safe works execution,

especially the wall surface where boxes and conduits are to be installed, (wall shall be painted minimum first coat of approved paint before installing the boxes and conduits). - After verifying the exact location and provided all the necessary mark out, start installing the box by drilling in the concrete wall, column, or ceiling and fixed the box using anchor bolt (plastic or metal anchor).

- Electrical Metallic Tubing (EMT) shall be used for exposed fixings and above false ceiling wherever applicable as per the project Specifications and approved Shop drawings.

- Rigid heavy gauge steel conduit is used for all exposed installation such as mechanical,

electrical equipment rooms and all hazardous area. Installation of Steel Conduits - Ensure that the boxes are Inspected fort alignment, height, distances, flatness after fixing and bolts/screw are securely fastened.

- The conduits on walls are to be run neatly, horizontally or vertically as may be required as per the approved Shop drawings. Types of Conduits

- After installation of the boxes, fix conduits. Conduit shall be securely fastened in ceiling, or wall using approved double hole clamp not exceeding the distance specified in project specifications.

- Where a conduit enters a box, fitting, or other enclosure, a bushing & locknut shall be provided to protect the wire from abrasion unless the design of the box, fitting, or enclosure is such as to afford equivalent protection.

- The outlets do not run more than the permissible numbers of conduits to any surface wall outlet Installation of Steel Conduits

- The exposed conduit work is to be installed so as not to interfere with ceiling inserts, lights or ventilation ducts or outlets

- Thread less couplings and connector used with conduit shall be made tight. Where installed in wet locations, they shall be the rain tight type. Thread less or screw type couplings and connectors shall not be used on threaded conduit ends unless listed for the purpose. Installation of Embedded Conduits in Slab and Walls

- Ensure that conduit connections are wrench tight.

- Provide pulling wire (Gl wire or equivalent strength cord) in each conduit. Secure the wire inside the box or at end of conduits and covered. Channel erector system components (Unit strut or similar) used to support conduits, cable trays, enclosures, lighting fixtures and other electrical equipment shall be made hot-dip galvanized (preferably). Electrical Conduit Installation Guide

- All field cuts unit-strut shall be touch up with approved paint

- Any changes in the routing of conduits shall be mark in the as built drawing.

- All installed conduits to be protected until the next activity and final handover.

5.4 Installation of Embedded Conduit in Slab and Walls (PVC, RGS):

- PVC conduits in reinforced concrete structures are generally to be installed after placing

reinforcement and before concreting, using the steel boxes and fittings such as coupling,

adapters with locknuts, and PVC solvent. Sizes of conduits and boxes to be installed as per approved shop drawings. Electrical Conduit Installation Guide - PVC Conduits shall only install embedded in concrete slab or block work, exposed PVC

conduits works is not permitted. - Survey and marks out the exact location of all boxes, conduits in the slab and walls.

- Ensure the coupling of conduit and termination into spouted fittings is to be made watertight and permanent using special cement.

- Ensure bending of conduits is done using appropriate methods without compensating the

internal diameter of conduits. Electrical Conduit Installation Guide - For bending purpose only bending spring or PVC elbow shall be utilized.

- Ensure the connect conduit terminating in switchgear, fuse boards, trunking adaptable boxes or other non-spouted enclosures etc., with smooth bore male PVC bushes and sockets. Installation of Embedded Conduits in Slab and Walls

- Ensure the semi-permanent adhesive use in joints requiring expansion couplers.

- Ensure the ends of conduit and conduit fittings are to be cleaned and jointed using

- PVC cement recommended by manufacturer.

- All box unused opening shall be closed using masking or duct tape.

- Provide pulling wire (Gl wire or equivalent strength cord) in each conduit. Secure the wire inside the box or at end of conduits. Types of Conduits

- All conduit stubs up are properly capped until wiring conductors are drawn in.

- All installed conduits to be protected until the next activity and final handover.

- Any changes in the routing of conduits shall be mark in the as built drawing.

5.5 Standard Procedures:

- All equipment’s connected to power supply must be grounded.

- All metal parts, structural steel, cable trays, piping, reinforced concrete must be grounded. Types of Conduits

- All joints shall be according to shop drawing. Types of Conduits

5.6 Safety Control:

A. Safety Rules during Conduits Installation Activities

- All hand tools and power tools shall be good in quality and working condition.

- Personal Protective Equipment (PPE) required varying type of works.

- Always check and inspect if the scaffolding, ladder used for fixing supports, boxes and

conduits are on safe condition and position before starting the work activities. - Be sure that all access for installation of fixing supports, boxes and conduits have no

obstruction at all times that may cause accident. Types of Conduits - Safety sign board, barricades shall be erected to the working areas i f required.

- Ensure good housekeeping at all times, keep work area clear from obstruction.

- Traffic Management Arrangements, Access & Egress – Security Measures shall be

provided. Types of Conduits

B. Emergency Arrangements

- General: Site general safety procedures will be followed. In case of emergency the Safety Officer or the most senior employee present will stop the work, and make the necessary emergency arrangements and report to the assembly points as described during Site Induction Course. Types of Conduits

- Fire Precautions: No significant fire risks associated with this activity but general fire

precaution measures will be taken as per Client instructions. - Communication from site areas to Site Office via mobile phones (Bravo) issued to all

engineers. In emergency situations the users of mobile phones (Bravo) to be notified if

deemed that this can speed up notification of relevant personnel and/or the Project Site

Clinic. Electrical Conduit Installation Guide

5.7 Inspection and Testing Procedures:

A. Inspection

- The conduit, boxes and fittings shall be given a visual inspection by the Engineer during the installation. Installation of PVC Conduits

- The Contractor should not allow any backfilling of trenches or pits where these systems are installed before inspection by the Engineer and the appropriate documents are signed. Installation of Electrical Conduits

- Material delivered shall be inspected under the Engineer’s supervisor about size, quality and quantity.

- Shop-drawing approved.

- Material approved.

- Check installation (connection, routing, and quantity) according to approved shop drawings. Types of Conduits

- Check dimension, level and finishing of conduits, boxes and fittings.

- Check installation according to approved shop drawings and manufacturer’s recommendation. Installation of Electrical Conduits

5.8 STATUTE OF COMPLETION:

After finishing the installation works of Grounding System, inspection shall be carried out and approved by relative parties such as: Consultant, Parson and civil defense. Installation of Embedded Conduits in Slab and Walls

OTHER POSTS:

-

Method Statement for Electrical Wires and Power Cables Installation

-

Method Statement for Interior and Exterior Lighting System Installation

-

Method Statement for Installation of Cable Tray or Trunking

-

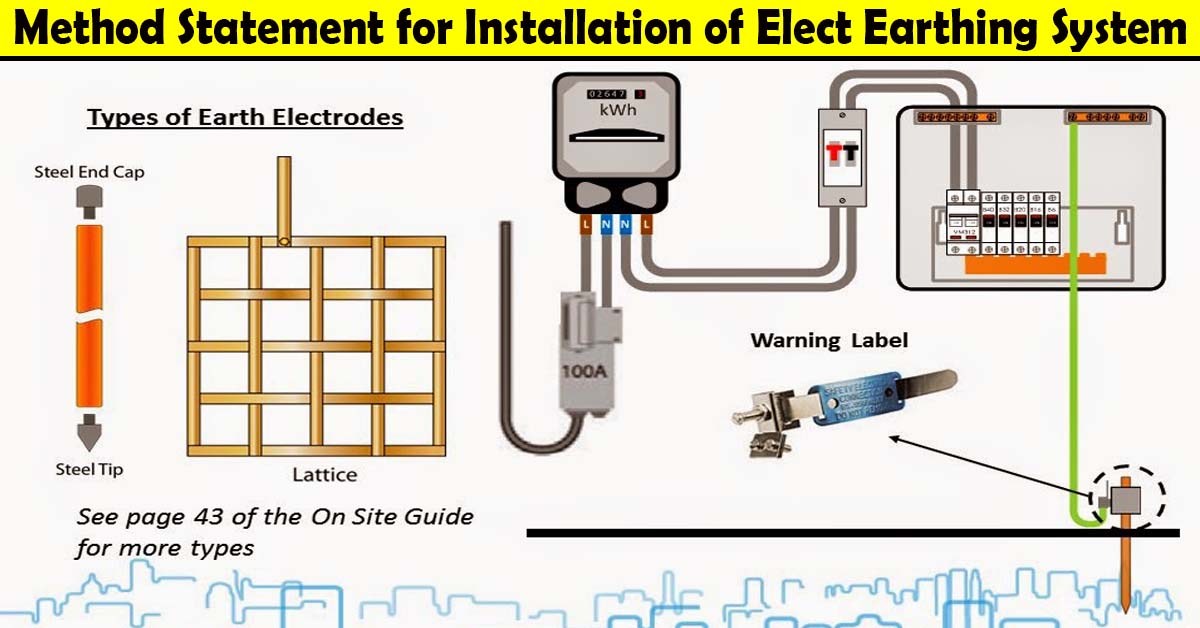

Method Statement for Earthing and Lightning Protection System

Conclusion:

Full article on Installation of Electrical Conduit and Boxes | Installation of PVC Conduits | Heavy Gauge PVC Conduits | Installation of Flexible EPVC Conduits | Installation of Steel Conduits | Installation of Embedded Conduits in Slab and Walls | Installation of Electrical Conduits | Types of Conduits | Electrical Conduit Installation Guide. Thank you for the full reading of this article in “QA QC in Construction” platform in English. If you find this post helpful, then help others by sharing it on social media. Please share this article on social media for future uses.

hi

how to i get all the electrical method of statements.

Thanks.

Thanks for comments please get in touch for more knowledge. I will upload more soon