Last updated on: November 3, 2024

Are you in the construction field and looking to streamline your project’s reinforcement plan? Understanding the Bar Bending Schedule (BBS) is essential for accuracy, efficiency, and cost-saving in construction.

In civil engineering, the Bar Bending Schedule (BBS) is key. It gives details on reinforcement bars for concrete structures. It shows the size, shape, bends, length, and weight of each steel bar needed for a project.

This schedule is vital for placing bars correctly in beams, columns, slabs and footings. It’s crucial for the structural integrity and quality control of a project.

We’ll dive into BBS, from calculating cutting lengths to creating a well-prepared BBS format. It’s essential for construction pros. It helps figure out steel needs, cuts down on waste, and meets reinforced concrete design standards.

Before reading this article, you must read about the following:

- Main Bars and Distribution Bars

- Bar Bending Schedule Formulas

- Why Crank Bars are Provided in Slab Beam and Column

- Development Length

What is Bar Bending Schedule and why it is important?

A Bar Bending Schedule (BBS) is a detailed document outlining the specific requirements for reinforcing bars (rebar) used in a concrete structure. It provides essential information for fabricators and contractors to accurately cut, bend, and place the rebar according to the structural design.

The BBS typically includes:

- Bar Mark/Number: Unique identifiers for each type of bar.

- Type and Size: Descriptions of the bars, including diameter and shape.

- Length: The total length of each bar.

- Bending Details: Specifications for any bends or hooks required in the bars.

- Quantity: The number of bars required for each configuration.

This table helps manage materials accurately and makes sure the construction follows engineering standards.

Key Benefits of Using a Rebar Bending Schedule in Construction

- Accuracy: On construction sites, it ensures accurate placement of reinforcements in beams, slabs, etc., thereby increasing the sturdiness of a structure.

- Efficiency: Assists in estimating the quantity of steel required with precision, hence minimizing the amount of rebar ordered and expenditures.

- Guidance: It offers construction employees information regarding how much, where, when, and how to cut, bend, and place reinforcement, which improves the construction process.

- Quality Control: Ensures that engineering designs and building codes are followed and the quality is retained.

- Inventory Management: Helps in the maintenance of steel stocks appropriately, neither deficiency nor surplus.

- Time Management: Saves time through the provision of guidelines on how and when to embed the reinforcement.

Using a BBS helps ensure that construction projects are efficient, cost-effective, and up to standard.

Components of a Bar Bending Schedule

A bar-bending schedule typically consists of a table with rows and columns. The rows represent individual bars or groups of bars, and the columns contain information about the size, shape, cut length, bending and other specifications of the bar(s).

Some examples of columns that may be included in a bar bending schedule (steel bending schedule) table are:

- Bar number: A unique identifier for each bar or group of bars.

- Shape: The shape of the bar, such as circular or square.

- Size: The diameter or width of the bar.

- Bar Cutting Length: The bar cutting length is a length of a rebar (reinforcing bar) that needs to be cut and bent to the specified shape and dimensions. This can be find by using bar bending schedule formulas.

- Total Length: The total length of the rebar, including cutting length or any additional length needed for overlap or for projecting beyond the end of the concrete element.

- Quantity: The number of bars in each group.

- Weight: The weight of each bar or group of bars.

- Bending radius: The required radius for any necessary bends in the bar.

- Location: The location of the bar within the structure, such as “foundation” or “beam.”

- Purpose: The purpose of the bar, such as providing structural support or reinforcing a specific area.

- Notes: Any additional information or comments about the bar or its placement in the structure.

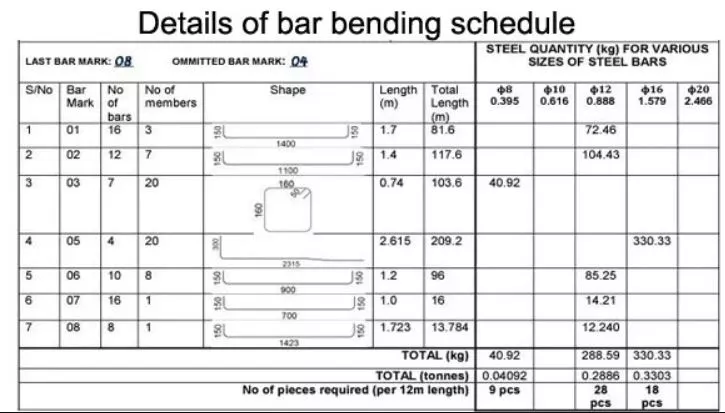

Example BBS Format

Here’s how these components might be organized in a table format for a Bar Bending Schedule:

| Bar Mark | Type | Size (mm) | Cutting Length (mm) | Total Length (mm) | Quantity | Shape | Bending Radius (mm) | Location | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Y10 | 10 | 1500 | 1600 | 5 | Straight | – | Beam | 0.78 |

| 2 | Y12 | 12 | 2000 | 2100 | 3 | Hook | 100 | Column | 1.13 |

| 3 | Y16 | 16 | 2500 | 2600 | 4 | Bend | 150 | Slab | 2.01 |

| 4 | Y8 | 8 | 1200 | 1300 | 10 | Stirrups | – | Foundation | 0.50 |

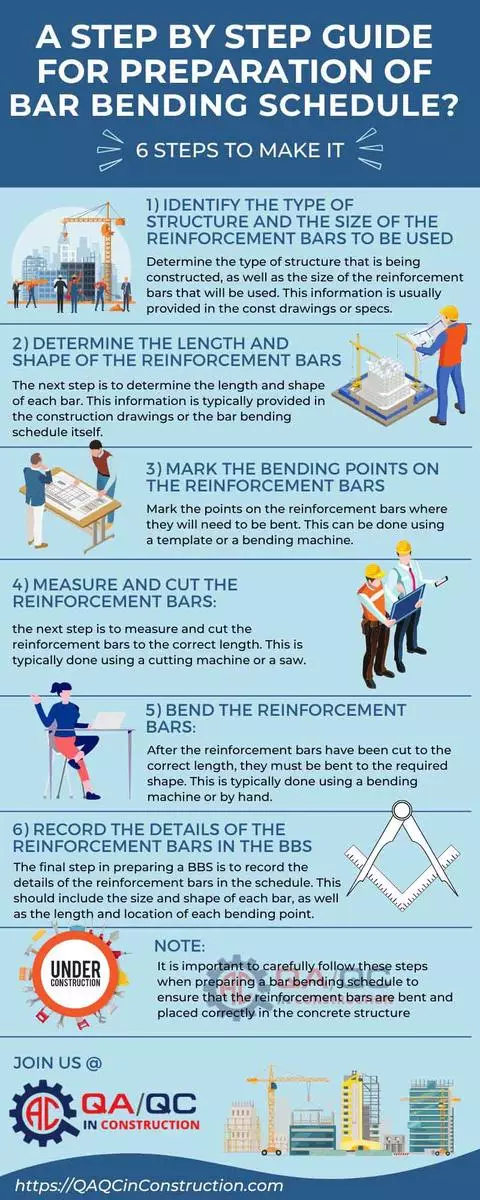

How to Prepare a Bar Bending Schedule (Step by Step)

The process of creating a Bar Bending Schedule is a systematic process that helps to make ensure that the reinforcement bars are accounted for accurately on a construction project. Here are the essential steps to prepare an effective BBS:

Step 1: Review Structural Drawings:

First, you go over the structural drawings and specifications for the project to understand what’s happening. By doing this, all the concrete elements that have to be reinforced will be identified.

Step 2: Identify Reinforcement Requirements:

Decide what kinds and how much reinforcement bars are required for each structural element that includes beam, columns and slab.

Step 3: Calculate Bar Lengths:

Work out the cutting lengths fixed for all types of bar according to design specifications. That includes looking at any bends or hooks they will need to incorporate.

Step 4: Determine Number of Bars:

According to structural design guidelines and prescribed spacing, determine how many bars are required for each type, and count the total number of bars needed overall.

Step 5: Specify Bending Details:

Find out the bending shapes, angles, for each bar. Describe these bends clearly using standard shape codes (e.g. BS 8666).

Step 6: Create a Table Format:

All the collected data to a clean organized table. Essential columns should include:

- Bar Mark

- Type and Size

- Cutting Length

- Quantity

- Shape Code

- Location

- Weight

Step 7: Include Additional Information:

Write any notes really relevant to special instructions, revisions, or particular handling including each type of bar.

Step 8: Review and Verify:

Then review the BBS to ensure that it’s accurate and complete once written. Compare with structural engineers or project manager to the project details to ensure they match requirements.

Step 9: Finalize and Distribute:

Once verified, finalize the schedule and send it to steel suppliers and the on site workers to pinpoint requirements needed from all parties involved.

Step 10: Monitor During Construction:

Always refer back to the BBS during the construction process to monitor progress, and to make any necessary changes to your design or quantities if your design or quantities should change.

Notations in Reinforcement (Steel Bars) Detailing:

n reinforcement detailing, various notations and symbols are used to convey important information about steel bars (rebar). Here’s a detailed overview of common notations used in the industry:

1. Bar Marking and Quantity

- Bar Mark: Identifies a unique Type of rebar as defined in the Bar Bending Schedule. (eg 21)

- Quantity: Previous mark (indicated before the bar mark) of number of bars needed (for example, 13 bars).

2. Steel Grade and Size

- Steel Grade: Which quality of the steel this is indicated by a letter (e.g. ‘B’ for Grade B steel).

- Diameter: The rebar size normally expressed in millimeters (e.g., B25 indicates a 25mm diameter bar).

3. Shape Codes

- Shape codes describe the configuration of the bars:

- 00: Straight bar

- 11: L-bar (90-degree bend)

- 21: U-bar (180-degree bend)

4. Location Notations

- Location codes indicate where the bars are placed within the structure:

- T: Top layer

- B: Bottom lay

- NF: Near face

- FF: Far face

- EF: Each face

5. Spacing and Cover

- Spacing: Integer multiples of ‘mm’ is used as the distance between adjacent bars (e.g. ‘150mm c/c’ (center to center) is 150mm spacing)

- Cover: Millimeters of distance between the rebar and the surface of the concrete.

6. Bending Radius

- The radius required for any bends in the rebar is often denoted as:

- s=100mm or 2d, where “d”, is the specimen diameter.

7. Additional Notations

- Other abbreviations may include:

- REINF: Reinforcement

- THK: Thickness

- UB: U-bars

- LB: L-bars

- LINKS: Something similar to a code in standards.

Example of a Typical Notation

A notation might look like this:

14 H25 18-200 B1

This translates to:

- 14: Quantity of bars

- H25: Grade H steel, with a diameter of 25mm

- 18: Bar mark or shape code

- 200: Spacing between bars in millimeters

- B1: Indicates it is the first bottom layer of reinforcement.

Importance of Understanding Notations

Understanding these notations is important because:

- Helps to correctly read and understand reinforcement drawings.

- Ensures the right types and amounts of rebar are used.

- Aids clear communication among engineers, contractors, and workers.

By knowing these notations, construction professionals can make sure the building is strong and safe throughout the construction process.

Types of Steel Reinforcement used in Construction Projects:

Depending upon the yield strength, steel reinforcement is classified in the construction projects. Here are the common types:

Mild Steel Rebars:

- Yield Strength: Approximately 250 MPa.

- Usage: Used in light structures and projects where only easy bending and easy welding are needed.

High Yield Strength Deformed (HYSD) Bars:

- Yield Strength: Typically around 415 MPa.

- Usage: Most popular for better strength and bonding to the concrete in residential and commercial buildings.

Thermo-Mechanically Treated (TMT) Bars:

- Yield Strength: The range varies by the grade of the cut (e.g., Fe 415, Fe 500, Fe 550, Fe 600): 415 MPa to 600 MPa.

- Usage: High strength, high ductility; used widely in high rise buildings, bridges, and other large infrastructure projects.

Cold Twisted Deformed (CTD) Bars:

- Yield Strength: Around 415 MPa.

- Usage: However less common now, and used in other structures which benefit from the twisting process for the extra strength.

High-Strength Steel Rebars:

- Yield Strength: Above 600 MPa.

- Usage: Special applications requiring very high strength, such as nuclear plants, high performance structures.

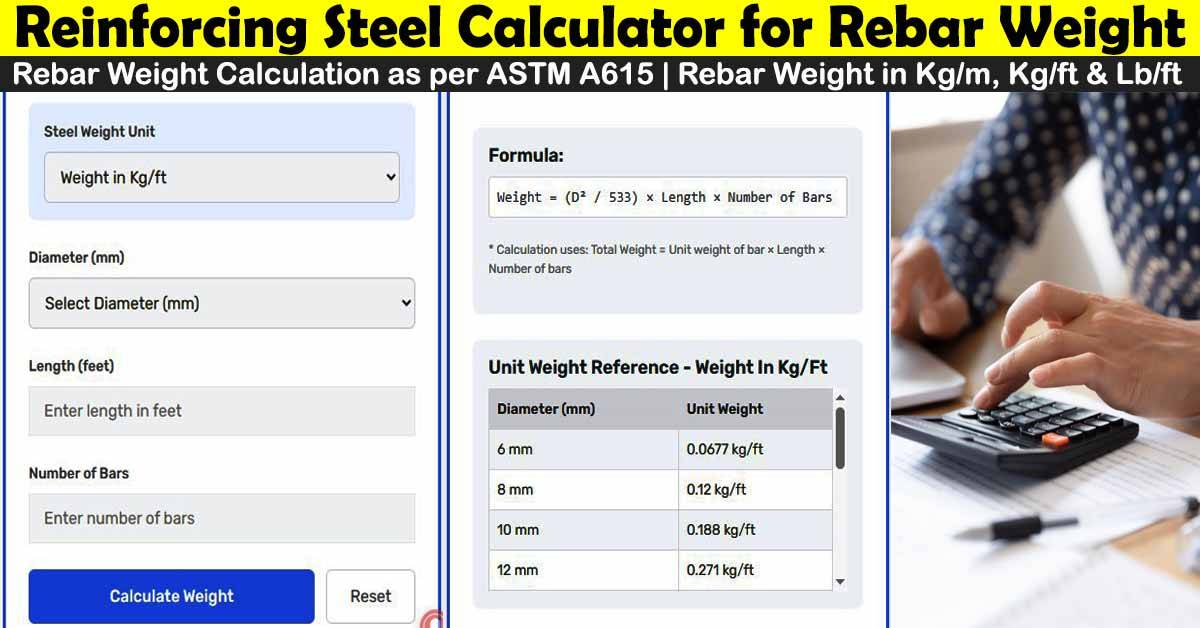

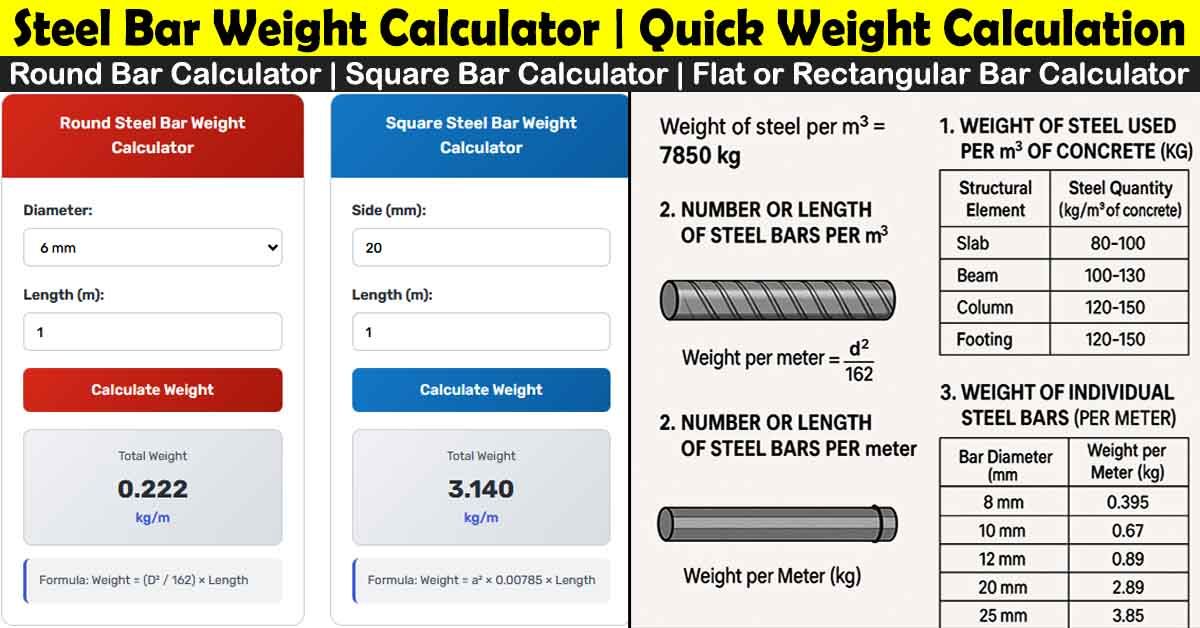

Read More about: Steel Weight Calculator for One Way Slab

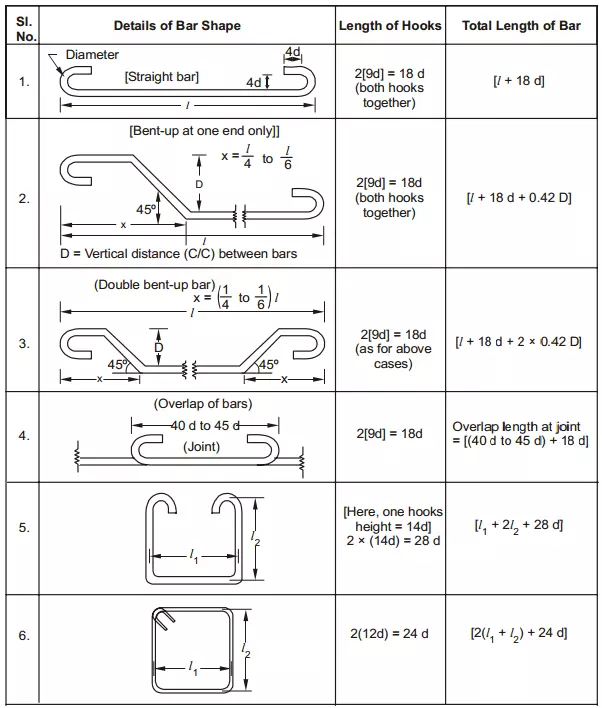

Bar Bending Schedule Formulas:

Applications of a Bar Bending Schedule in the Construction Industry

In the construction industry, BBS is used in many projects, including:

- High-Rise Buildings: It ensures the steel reinforcement is placed correctly, keeping the building strong.

- Bridge and Highway Projects: These need a lot of reinforcement steel, so an accurate BBS is key.

- Residential and Commercial Buildings: BBS helps figure out how much steel is needed, making material management better.

The use of BBS is vital in all reinforced concrete projects. It makes sure the placement of reinforcement meets the structural drawings exactly.

Challenges in Preparing an Accurate Bar Bending Schedule

Creating a BBS is a detailed task that needs careful calculations and checks. Here are some common problems:

- Complex Calculations: Doing calculation of cutting and bending by hand can lead to mistakes.

- Interpretation of Design Drawings: Misunderstanding design requirements can result in wrong bar sizes or bending angles.

- Time-Consuming Preparation: Making a bending schedule for big projects takes a lot of time.

Solutions:

- Automated BBS Software: New software can automatically make BBS, ensuring it’s right.

- Double-Checking Measurements: Checking each bar’s details against the structural drawings helps avoid mistakes.

- Standardized Templates: Using the same BBS templates makes things more accurate and faster.

BBS Formats and Tools for Streamlined Preparation

There are many ways to format and prepare a BBS:

- Excel Templates: These are common and can be customized. They’re great for smaller projects with simple bending or shaping needs.

- Specialized BBS Software: Some software tools are made to make BBS creation easier. They help reduce mistakes and give detailed information about the reinforcement.

- Manual BBS: This method is used for smaller projects. It’s time-consuming and less efficient for big builds.

Choosing the right format for each project is key. It helps in efficient BBS preparation and steel bar estimation.

Case Study: BBS in Real-World Construction Projects

Here’s a case study highlighting the use of a Bar Bending Schedule in a real-world construction project:

Project Overview: A 30-story commercial tower in a metropolitan city was planned, to be built on a high rise building project.

Challenge: The efficient managing of the extensive use of reinforcement bars (rebar) to meet structural integrity and cost efficacy.

Solution: Bar Bending Schedule design and implementation.

Process:

- Preparation: A comprehensive BBS was prepared by structural engineers with the specifications for the size, shape, length, and bending demanded for each rebar.

- Coordination: The construction team, including steel suppliers, fabricators, and site workers, shared the BBS.

- Execution: During the cutting, bending, and placement of rebar, the BBS provided direction so that everything cut, bent, and positioned was accurate and to design specifications.

- Monitoring: Errors and rework were minimized with a process of regular inspections of the BBS to verify compliance.

Results:

- Efficiency: The BBS streamlined the rebar installation process, reducing construction time by 15%.

- Cost Savings: Accurate estimation of rebar quantity reduced wastage by 10%, resulting in significant cost savings.

- Quality Assurance: The precise placement of rebar ensured the structural integrity of the building, meeting all safety standards.

Bar Bending Schedule Download (Excel File)

BBS Sample Excel File Download

This is a Bar Bending Schedule example that you can download for your knowledge and practice.

Conclusion: The Essential Role of Bar Bending Schedule in Reinforced Concrete Construction

A Bar Bending Schedule is more than just a list of steel reinforcement requirements. It’s vital for quality control and structural integrity in every reinforced concrete structure. A detailed BBS helps construction teams be more accurate, use materials better, and follow safety rules.

The BBS makes construction smoother, leading to better project delivery and quality.

Whether you’re a civil engineer, contractor, or project manager, knowing how to make an accurate bar bending schedule is crucial. Use BBS for better efficiency, lower costs, and stronger projects.

OTHER POSTS:

- 30+ Bar Bending Schedule Formulas | BBS Steel Calculation

- Method Statement for Cutting and Patching Works

- Method Statement for Cast in Place Concrete Works

- Method Statement for Bituminous Damp Proofing for Concrete and Masonry

- Method Statement for Trench Excavation and Backfill for Electrical Cables

FAQs:

What does BBS stand for in construction?

BBS stands for Bar Bending Schedule in construction.

What is LD in bar bending schedule?

Development Length (LD) usually refers to the length required for a structure in the rebar context of a Bar Bending Schedule. This is the rebar that should be embedded in concrete to reach its full strength. Knowing the development length assures us that the rebar can properly carry loads to the surrounding concrete and not slip. It is determined by the factors such as bar diameter, strength of concrete, and type of stress applied

Who Prepare bar Reinforcement schedule?

A bar bending schedule or rebar bending schedule is typically prepared by a structural engineer or a rebar detailer.

Why Steel Reinforcement used in RCC structures?

Steel reinforcement is used in reinforced concrete (RCC) structures to improve their strength and ductility. Concrete is a strong and durable material, but it is brittle and does not have much tensile strength. Steel, on the other hand, is strong in both tension and compression, and it has good ductility (the ability to deform without breaking).

What is Cutting Length in Bar Bending Schedule?

Cutting length is the length of a reinforcement bar after it has been cut to size and bent to the required shape.

How I prepared Bar Bending Schedule PDF?

– Create a Table: The way to go is to create a table with necessary columns using spreadsheet software like Excel or Google Sheets.

– Input Data: Input data for each of the bars as — bar mark, shape, size, length, quantity, weight, and bending details.

– Calculate Weight: Using that formula, calculate the weight of each bar.

– Format the Table: Format the table to make it easier for others to read and understand.

– Add Diagrams: Good way to include diagrams to show complex bends and hooks.

– Export to PDF: The table can be easily printed and shared via a PDF document.

Reinforcement detailing can also be facilitated by more specialized software in which many of these steps would be automated and one would end up with nicely detailed BBS PDFs.

Standard Codes for Steel Bar Bending Schedule?

By following specific standards the preparation of a Bar Bending Schedule (BBS) is to ensure safety, consistency and accuracy in construction.

IS 2502: 1963 (Indian Standard) – A popular standard in India prescribing bending and steel reinforcement bar placement. It determines the manner to be used for calculating the length and bending requirements, and includes standard shapes of steel reinforcement.

BS 8666 (British Standard) – Widely used in the UK – This is used to set out requirements for the scheduling, dimensioning, bending and cutting of steel reinforcement for concrete. Additionally, it gives information about the codes used on bar shapes.

ACI 315-18 (American Concrete Institute) – Common reference is to ACI 315, which in the US establishes guidelines for detailing and scheduling reinforcement bars for reinforced concrete.

Eurocode 2 (European Standard, EN 1992-1-1) – This is used throughout Europe, which has a comprehensive approach to the design of concrete structures, and defines the specifications for steel reinforcement bars and their bending schedules.

ASTM Standards – In the North America – ASTM A615, ASTM A706 are among the most commonly referred standards for steel reinforcing bars (mesh) with material properties and mechanical requirements for reinforcing bars used in reinforced concrete.

Magnificent

Thanks for comment, For more related posts please visit Civil, Arch, Electrical and Mechanical Tab in File menu

Very good,this article is very interesting and helpful for me .Thanks.

Thanks for your comments. Please get in touch for more knowledge.

this article is very helpful for me

Thanks for your comments. Please get in touch for more knowledge.